PROCESS TECHNOLOGY SOLUTIONS FOR HARSH AND CORROSIVE PROCESS STREAMS

Process Technology Solutions for Harsh and Corrosive Process Streams

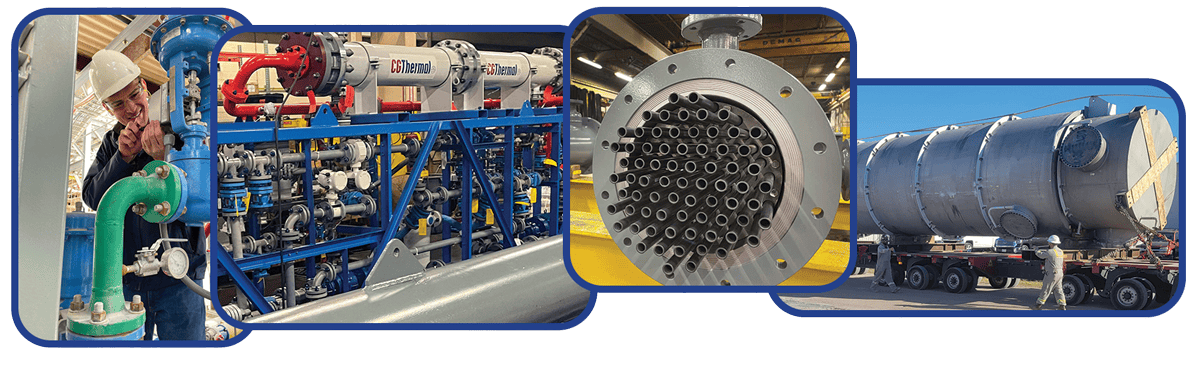

CG Thermal – Heat and Mass Transfer Experts • Process Modeling, Acid Processing, and High Temperature Gas-to-Gas Design

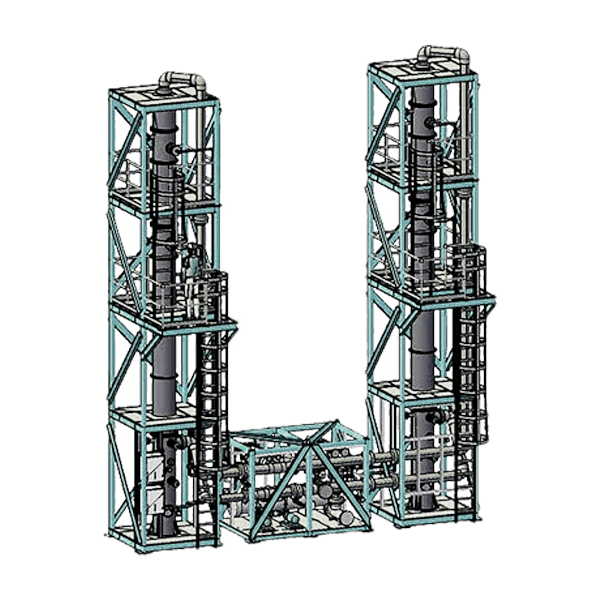

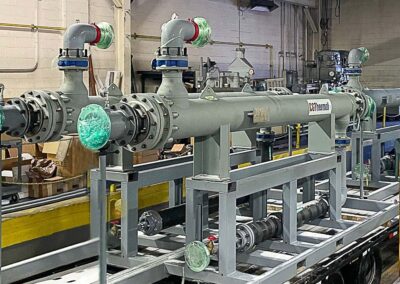

Process System Design and Turnkey Solutions

Process System Design

Our team of experts will assist you in designing a custom and optimal solution for the application at hand.

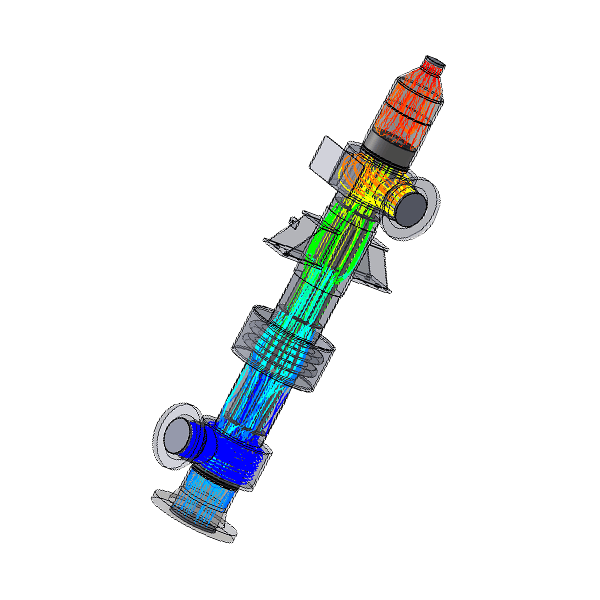

High-Temperature Engineered Solutions

In-house temperature and flow mapping to eliminate thermal stress and corrosion for improved plant reliability.

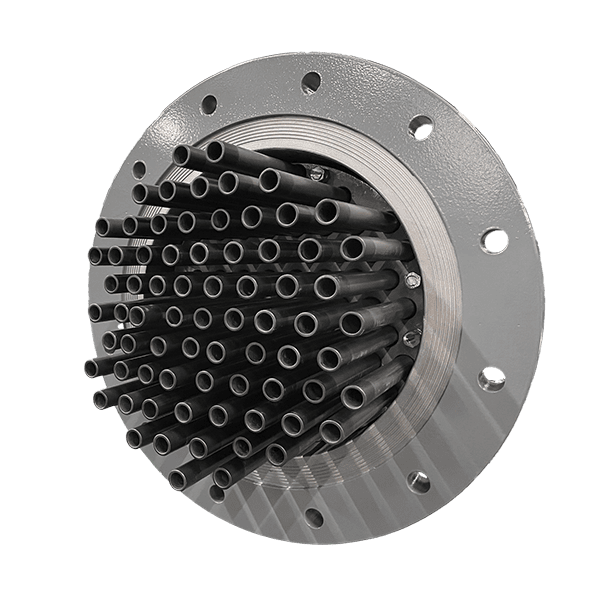

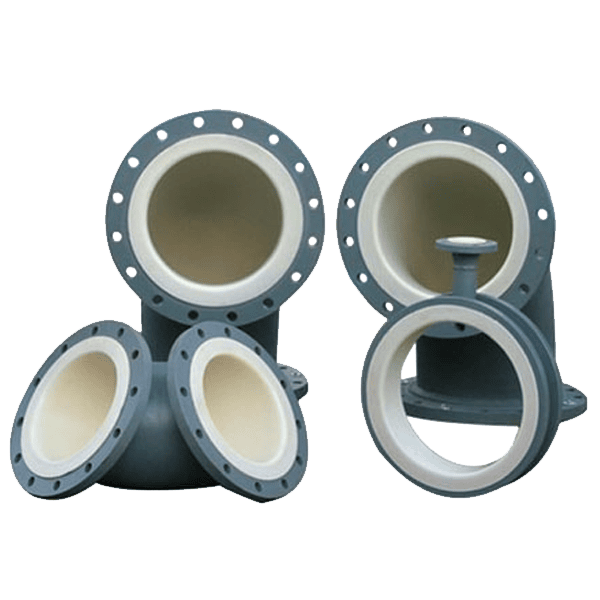

Umax® Advanced Ceramic

The most universally corrosion-and-erosion resistant material in the chemical processing industry.

Impervite® Advanced Graphite

Next generation, award-winning graphite with a completely field-repairable design.

See What Our Customers Are Saying

Contact Our Team

At CG Thermal we are decidedly customer-focused, and approach each new project with a desire to achieve our customer’s goals and process requirements in the most efficient and cost-effective manner. We have particular expertise in corrosive and high temperature process streams, and provide a range of services from individual equipment to full turnkey systems to engineering design and plant layout consulting.

Let’s discuss your harsh and corrosive process stream today!

Company Bulletin

Thank you for your interest in CG Thermal – Heat and Mass Transfer Experts and our products. We would be very interested in working with you to determine the equipment most suitable for your process. We hope to be responsive to your needs and work closely with you to be certain all your requirements are addressed. You can Download our heat exchanger product bulletin here for your reference.

From Our Blog

White Paper: Material and Design Upgrades to Graphite Heat Exchangers

White Paper Preview Material and design upgrades to graphite heat exchangers are often necessary when operating life falls short of expectations. Graphite heat exchangers have long been trusted in hydrochloric, sulfuric, and phosphoric acid applications due to their...

Chlorine Institute Annual Meeting 2026

Join us in Houston, March 23–26, 2026 for the Chlorine Institute Annual Meeting, Technology Symposium & Table-Top Expo. Find CG Thermal at the table-top expo March 24–25, and let’s discuss your harsh and corrosive process streams — including HCl Synthesis systems,...

SOCMA 2026 in Nashville

Join CG Thermal at SOCMA 2026 in Nashville, TN CG Thermal is heading back to Nashville for the SOCMA 2026 Specialty & Custom Chemicals Show, taking place March 4–6, 2026. You can find our team at Booth 1026, where we’ll be available throughout the show to connect...