Green Energy Solutions

High-Temperature, High-Pressure, Energy Capture & Storage, Turnkey SystemsCG Thermal provides numerous solutions for the Green Energy sector including high-temperature (up to 1200C+) gas recuperators, energy storage solutions, and full turnkey systems for green energy operations. Common green energy applications include high-temperature energy capture and storage, green hydrogen streams, CO2 carbon capture, biomass, and bioenergy recovery.

With our ability to custom design heat exchangers and process equipment to meet the precise requirements of our customers, our engineering team is well-suited to take on a variety of projects. The AirBTU VPRR and HTXP high-temperature gas-to-gas heat exchangers are the primary vehicle for these operations, offering industry-leading safety and reliability at stream temperatures of up to 1200C and above. Because each unit is custom-designed, the heat exchanger has the flexibility to address streams with high pressure and/or variations in flow-rate. Additionally, the unit can be designed to capture spent heat or steam, recapturing and reutilizing this otherwise wasted energy.

Among the critical factors that must be addressed during the design process is proper evaluation of thermal stresses, tube wall temperature, and pressure drop. It is important to design out the common failure modes and design in efficiency and reliability.

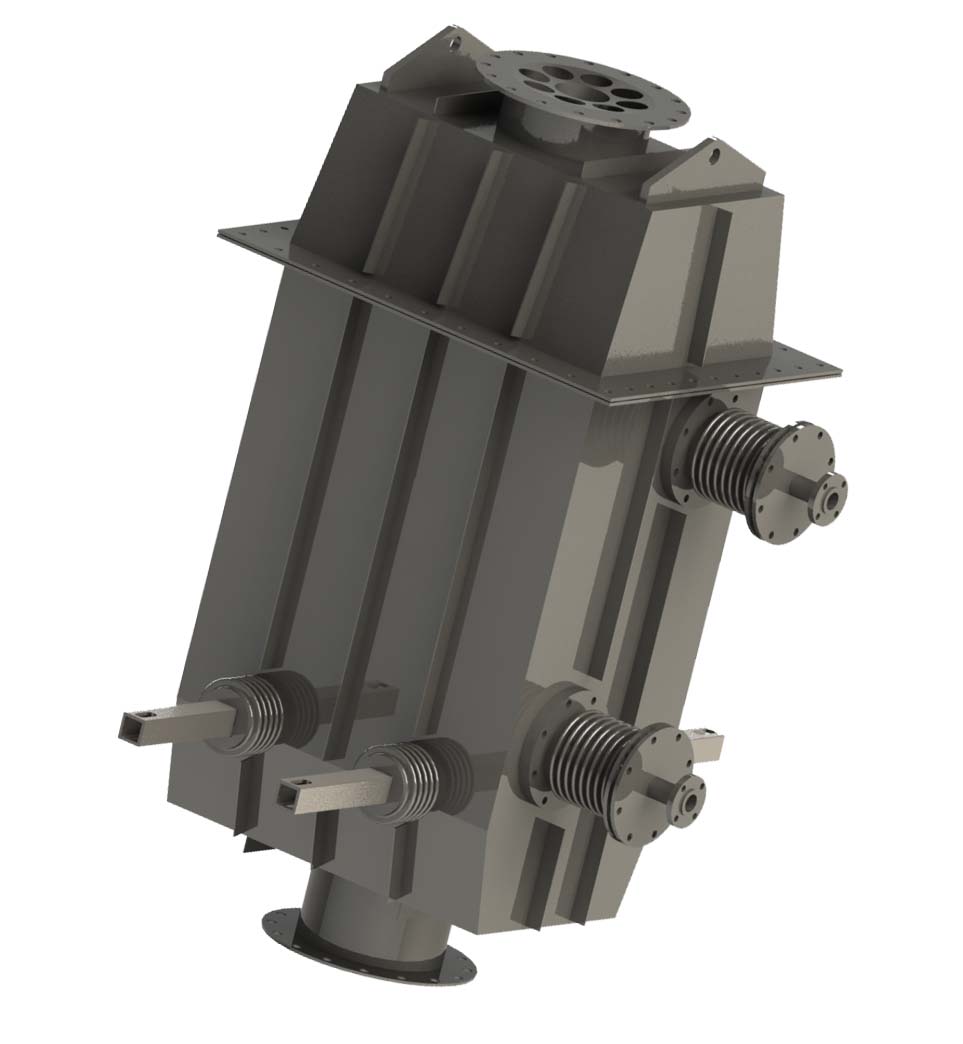

AirBTU HTXP High Temperature and High Pressure Exchanger

Using an innovative design including a novel application of high performance insulation the AirBTU HTXP allows for thermal expansion, without the material stresses typical in high-temperature and high-pressure process streams.

AirBTU HTXP features:

- Allows for thermal expansion without causing material stress

- Supports both high temperature and high pressure streams

- Eliminates hot spots and maintains suitable material temperatures

- Easy disassembly for repair and cleaning

- Optimal design allows for lower CAPEX

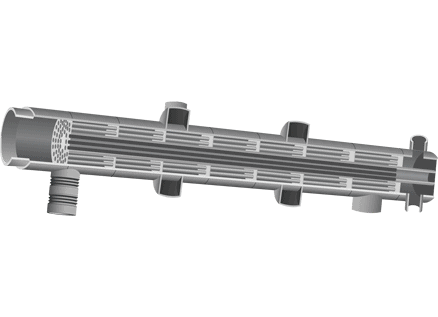

AirBTU VPRR High-Temperature Gas Recuperator

By integrating an AirBTU VPRR heat transfer solution, industry professionals can avoid common pitfalls and “design in” reliability and efficiency.

AirBTU VPRR features:

- Tube wall temperature mapping

- Eliminates stress failures

- Reduces pressure drops

- Maximizes thermal efficiency

- Minimizes maintenance downtime

Process System Design for Green Energy

Along with heat exchangers and process equipment, our team is capable of system design for your green energy operation. Each piece of the system will be chosen to optimize plant layout and function to maximize the OPEX of the plant.

- Turnkey Packaged System — Custom designed skid package system may include instrumentation, PLC, HMI, piping, electric and platforms, ladders, and other safety features per job requirements

- Consulting Services — Trouble-shooting, optimizing, and evaluating of existing plant operations

- Engineering Design Package — Complete engineering and operations design and documentation including Haz-Op review on customer site, and controls and control instrument loops

- Major Equipment Package — Exchangers, vessels, pumps, filters, controls, drums, tanks, etc.