Capabilities

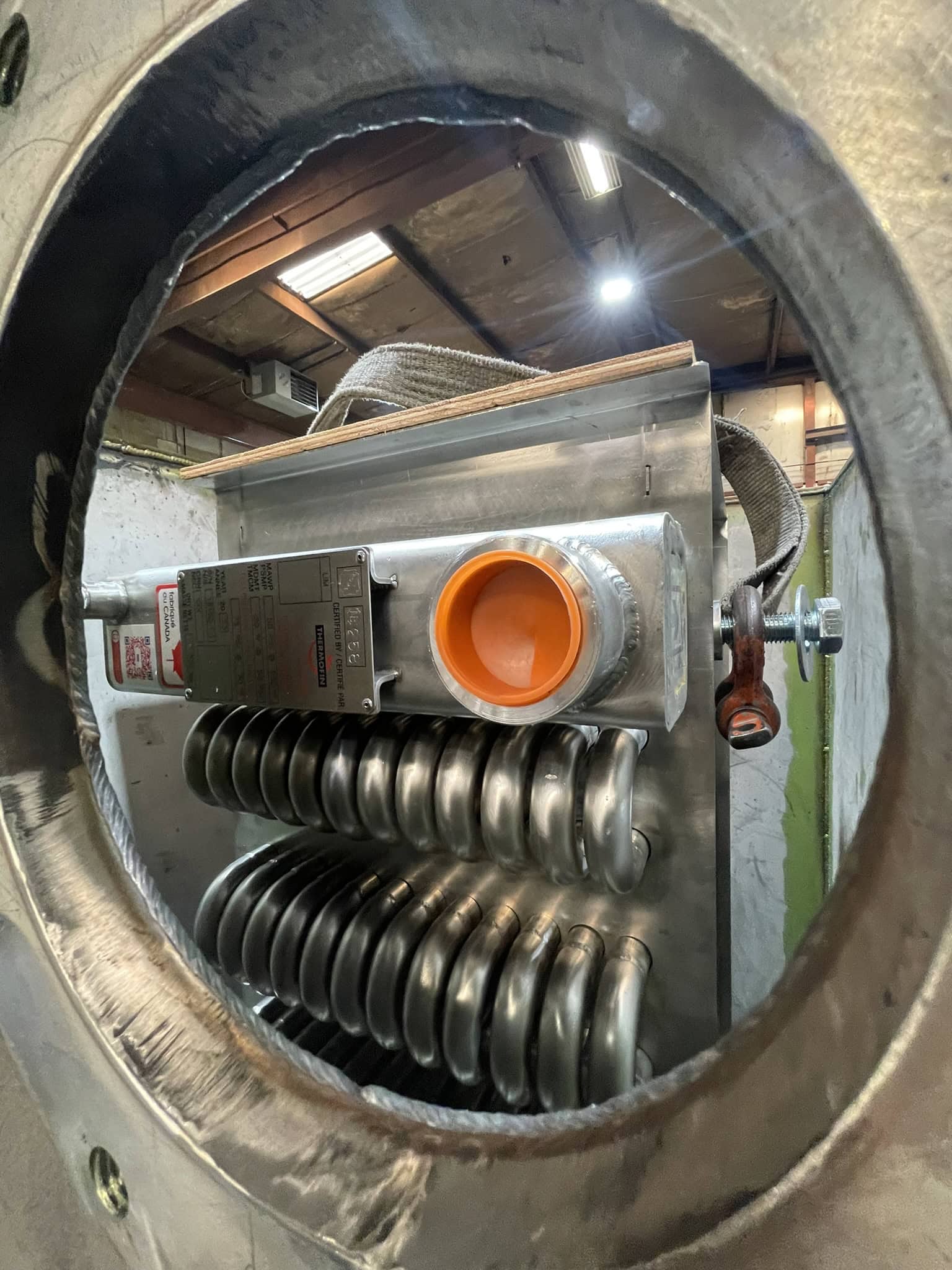

Custom Engineered Heat Transfer Systems

Heat/Mass Transfer Solutions

At CG Thermal, we specialize in process technology solutions for harsh and corrosive process streams and provide Custom Engineered Heat Transfer Systems. Our expert team offers a wide range of services including:

- Custom process equipment

- Technical support

- System evaluation and consulting

- Complete engineering packages

- Turnkey packaged and modular plant systems

The common goal is to help our customers maximize reliability, safety, and productivity while minimizing operating costs.

High-Temperature Engineered Solutions

With a hands-on approach and customer-focused discovery process, our engineers develop a plan to mitigate inefficiencies and improve plant reliability. Our team has a knack for understanding emerging markets and developing prototypes, as well as offering complete design and fabrication of pilot plants with novel requirements. Engineering analysis results are provided with or without a fabrication contract – we want to see your plant succeed!

What to expect:

- Site audit

- Engineering analysis and design

- CFD / FEA / ASME B31.3 analysis where applicable

- Duct strain analysis

- Fabrication and installation drawings provided

- Execution consulting available

- Materials and supplies recommendation

- Fabrication, controls and instruments, fan packages

Expertise and Innovation

Our design team includes mechanical and chemical engineers with significant expertise in specialized process technology solutions for harsh and corrosive process streams. We use advanced software in the design and fabrication of custom components to best meet your requirements. We listen closely to understand our customers’ needs and work as partners to provide the optimal solution.

Advanced materials that we provide include:

We also provide modeling and analysis expertise required for the success of systems operating with harsh and corrosive process streams, such as:

- Mass/heat transfer analysis including batch sizing

- Solid modeling with FEA and CFD analysis

The solutions we offer include, but are not limited to:

- Process System Design: Our extensive heat/mass transfer knowledge and fabrication capabilities, combined with our design and process expertise, enable us to develop and deliver services from engineering design to complete turnkey packages that fully meet our customers’ needs with the lowest possible CAPEX/OPEX. We have extensive expertise in:

- Sulfuric acid dilution and regeneration systems

- Hydrochloric acid system synthesis and conditioning systems

- Heat Exchangers: Our team can design and manufacture industrial heat exchangers tailored to the needs of a wide range of applications. We will recommend the most appropriate materials, and configuration to maximize efficiency and reliability, and address all site-specific concerns.

- Vessels: Whether a column, tank, or separation drum, our design will incorporate the most appropriate material to provide the desired operating life. These often include fluoropolymer linings. Glass or Fiberglass are also employed.

Other Technical Capabilities

In addition to engineered solutions, we provide many other services to our customers:

- Repair/refurbishment: We understand the importance of maintaining safe, reliable, and profitable operations. That’s why we offer repair, rebuild, and refurbishment services. Located in Ohio and Louisiana, we can handle requests for preventative refurbishment and emergency repair.

- Field service: We can supervise and/or perform equipment servicing across the globe. In addition to bringing a unit back into operation, our team is available for start-up inspection, hydro-testing, and training.

- Graphite impregnation: We impregnate customer-supplied graphite components with phenolic resin to increase strength and eliminate porosity. Our industry-leading, proprietary treatment is ideal for components integrated into heat exchangers, vacuum nozzle liners, column internals, and more.

Contact the Experts at CG Thermal Today

Whether you come to us for a turnkey system, engineering package, major equipment package, or individual custom components, we hope to be your indispensable resource by finding and supplying the best technologies, solutions, and expertise worldwide to improve your competitive position. If you want to learn more about our capabilities or discuss your heat/mass transfer needs with one of our team members, contact us today.