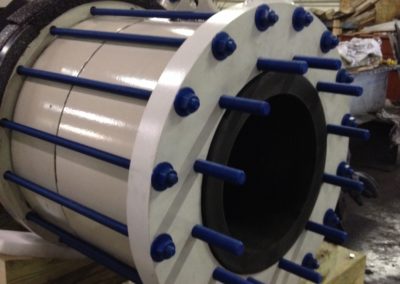

Impervite® Graphite Shell & Tube Heat Exchanger

Increase Your Plant Productivity With Our Shell And Tube Heat Exchangers

CG Thermal’s Impervite® graphite shell and tube heat exchangers are designed to be the workhorse of the industry. With over 200 years of combined experience, our key personnel bring time-tested designs and proven expertise to the design and manufacture of these and similar products. Utilizing our proprietary grade of phenolic impregnated graphite it offers excellent service life in corrosive condensing, vaporizing, absorbing, heating and cooling applications. Compared to other graphite heat exchanger designs it has competitive capital investment cost, high reliability, and high return on investment.

Impervite® is a composite material consisting of a graphite substrate impregnated using a proprietary phenolic impregnation process. Impervite is ideally suited for processing mixed acids, sulfuric acid, hydrochloric acid, phosphoric acid, nitric acid, waste acids, and chlorinated hydrocarbons. It has excellent machining, physical, and thermal properties.

Key Features & Benefits

- Designed and tested per ASME SEC VIII Div 1, TEMA, ANSI, ASTM, and stringent in-house standards.

- Large cross-sectional process flow areas for low pressure drop and/or high fouling applications.

- Up to 100 psig (6.89 barg) and 340 Deg F (171 Deg C) operating conditions.

- Exceptional fatigue resistance.

- High thermal efficiency.

- Tube diameter options include 7/8” (22 mm) and 1.50” (38 mm) inside diameter.

- Heat transfer areas range from 8 ft² (.74 M²) to 15,500 ft² (1,448 M²).

- State-of-the-art, in-house phenolic impregnation

- ASME Code stamp/ G-mark available

- Carbon steel/ SST/ Fluorpolymer lined shell options

- Multi-pass construction available

- Fully enclosed, skirted tubesheet design

- Flatplate graphite nozzle eliminates potential failure

- Many baffle materials to meet your requirements