High-Temperature Engineered Solutions

Temperature & Flow Mapping to Eliminate Thermal Stress & Corrosion for Improved Plant Reliability

Challenge Accepted!

The CG Thermal Experience:

- High-temperature design expertise

- Unique design for your unique reliability challenge

- Adaptable solutions for high-temperature

- Responsiveness and agility

- Transparency of results

- Customer input to ensure success

We want to see your plant succeed!

High-Temperature Engineered Solutions

With a hands-on approach and customer-focused discovery process, our engineers develop a plan to mitigate inefficiencies and improve plant reliability. Engineering analysis results are provided with or without a fabrication contract – we want to see your plant succeed!

What to expect:

- Site audit

- Engineering analysis and design

- CFD / FEA / ASME B31.3 analysis where applicable

- Duct strain analysis

- Fabrication and installation drawings provided

- Execution consulting available

- Materials and supplies recommendation

- Fabrication, controls and instruments, fan packages

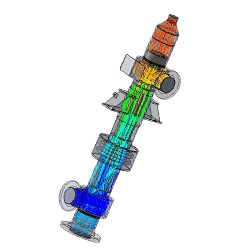

AirBTU VPRR High-Temperature Gas Recuperator

By integrating an AirBTU VPRR heat transfer solution, industry professionals can avoid common pitfalls and “design in” reliability and efficiency.

AirBTU VPRR features:

- Tube wall temperature mapping

- Eliminates stress failures

- Reduces pressure drops

- Maximizes thermal efficiency

- Minimizes maintenance downtime

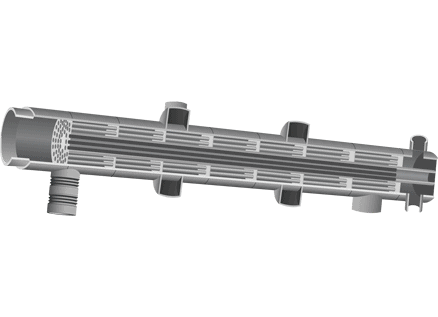

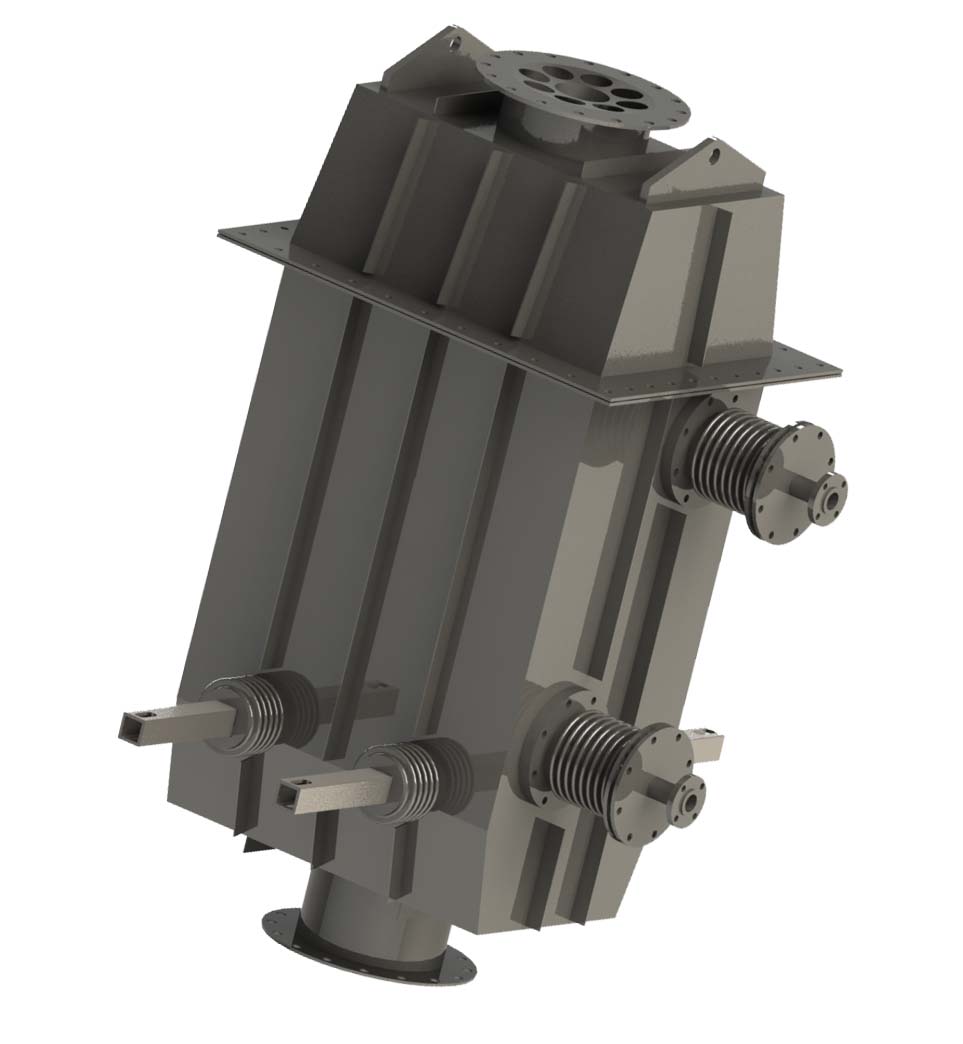

AirBTU HTXP High-Temperature and High-Pressure Exchanger

Using an innovative design including a novel application of high performance insulation the AirBTU HTXP allows for thermal expansion, without the material stresses typical in high-temperature and high-pressure process streams.

AirBTU HTXP features:

- Allows for thermal expansion without causing material stress

- Supports both high temperature and high pressure streams

- Eliminates hot spots and maintains suitable material temperatures

- Easy disassembly for repair and cleaning

- Optimal design allows for lower CAPEX

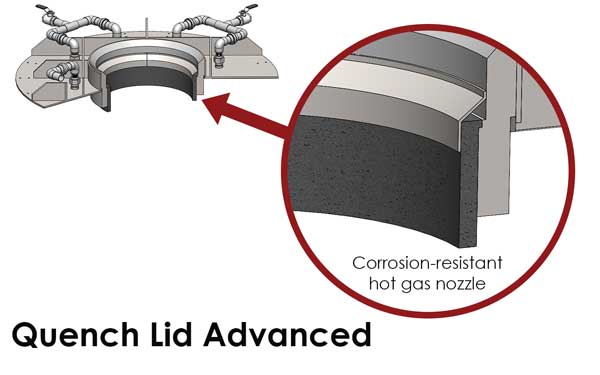

Quench Lid Advanced – Innovation for Quench Acid Gas / Adiabatic Coolers

In the case of quench gas coolers, adiabatic coolers, and hot gas scrubbers used in sulfuric acid regeneration plants, corrosion is an inherent and universal issue in the system. SO2 and SO3 gas typically enter the scrubber vessel from a decomposition furnace. As this hot gas enters, ambient temperature water is released from the lid above cooling the acid to near ambient. Typically, corrosion is imminent during this cooling process, as acid gas forms in the cooled stream.

Utilizing the Quench Lid Advanced eliminates corrosion on the gas nozzles, and in turn, significantly limits the area of corrosion. This greatly extends the life of the unit and prevents the premature failure inherent in these systems. This proven design can be used to manufacture new units or replacement scrubber lids can be retrofitted to existing ones, including designs utilizing wet-walled towers. The benefits of reduced downtime and increased production will result in lower OPEX and overall improved throughput of your plant.

Contact CG Thermal today, and let our engineering experts solve your unique design challenges. We’re here to help!