CRU Sulphur and Sulphuric Acid 2024 – Barcelona, Spain

Meet our team of experts at CRU Sulphur and Sulphuric Acid 2024 – Barcelona, Spain! Our engineers are eager to discuss your harsh and corrosive process streams, and how we can assist your plant with high-temperature engineered solutions. Using a variety of innovative technologies, novel materials, and industry-leading design techniques, we can assist in prototypes and pilot plants for many emerging markets. Coupled with our time-tested heat transfer solutions, we’ll be showcasing our AirBTU VPRR High-Temperature Gas-To-Gas Recuperator, capable of design-in reliability up to 1200C!

Meet our team of experts at CRU Sulphur and Sulphuric Acid 2024 – Barcelona, Spain! Our engineers are eager to discuss your harsh and corrosive process streams, and how we can assist your plant with high-temperature engineered solutions. Using a variety of innovative technologies, novel materials, and industry-leading design techniques, we can assist in prototypes and pilot plants for many emerging markets. Coupled with our time-tested heat transfer solutions, we’ll be showcasing our AirBTU VPRR High-Temperature Gas-To-Gas Recuperator, capable of design-in reliability up to 1200C!

Let us help you optimize your plant!

“For over 35 years CRU’s Sulphur + Sulphuric Acid has been the premier networking and professional development event for those involved in the production, consumption and trade of sulphur and sulphuric acid.

CRU curated quality content:

Hear from industry leaders and subject experts from around world and across the industry

Interact with speakers and SME’s via live streamed panel discussions and Q&A sessions

Build your personal agenda of must-attend sessions that will sync with your outlook or google calendar

Access to CRU’s industry analysts who will answer your questions and lead discussion sessions

Exhibition and branding opportunities:

Brand the event or specific spaces or functions

Design a rich, multimedia booth space where your team can interact with attendees

Receive rich analytics of your event experience”

We hope to see you there!

High-Temperature Engineered Solutions

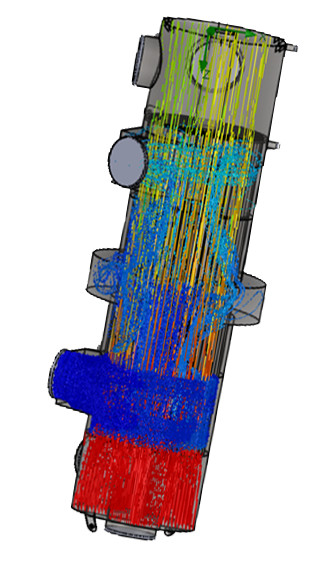

Unique customers and process streams require High-Temperature Engineered Solutions, with an emphasis on custom-tailored designs. Utilizing temperature and flow mapping, our engineering team develops a digital twin of the ideal unit for every individual stream to allow for accurate, true-to-life modeling. The result is industry-leading design solutions to eliminate thermal stress and corrosion common in these environments, offering improved reliability.

Unique customers and process streams require High-Temperature Engineered Solutions, with an emphasis on custom-tailored designs. Utilizing temperature and flow mapping, our engineering team develops a digital twin of the ideal unit for every individual stream to allow for accurate, true-to-life modeling. The result is industry-leading design solutions to eliminate thermal stress and corrosion common in these environments, offering improved reliability.

The CG Thermal Experience:

- High-temperature design expertise

- Unique design for your unique reliability challenge

- Adaptable solutions for high-temperature

- Responsiveness and agility

- Transparency of results

- Customer input to ensure success

AirBTU VPRR: High Temperature Energy Capture

Are you looking to improve the reliability of your high-temperature heat transfer equipment? By integrating our AirBTU VPRR heat transfer solution, industry professionals can avoid common pitfalls and “design in” reliability and efficiency. The AirBTU VPRR is designed to:

- Avoid cold-end corrosion. The introduction of low-temperature air can result in cold spots within a recuperator, causing condensation of some constituents of the process gas stream. The resulting reaction between this corrosive condensate and the heat exchanger surface is commonly referred to as cold-end corrosion. This destructive mechanism is “designed out” of the AirBTU VPRR, making it the ideal Heat Exchanger for Sulfuric Acid Applications.

- Eliminate stress failures. Temperature gradients across the tube bundle can lead to uneven stress concentrations at the tube-to-tube-sheet connections. These result in tubesheet failures with subsequent losses in production and costly repairs. We design in uniformity to eliminate this failure mode.

- Reduce pressure drops. Our VPRR features a proprietary design that reduces pressure drops for the best energy efficiency.

- Maximize thermal efficiency. Flow dynamics modeling is used to evaluate tube layouts and pass arrangements to create a symmetric design with optimal film coefficients and overall heat transfer rate. The resulting design requires less surface area and minimizes material and fabrication costs.

- Minimize maintenance downtime. In addition to minimizing failures caused by cold end corrosion and uneven mechanical stresses, we can “design-out” the potential for fouling.

Innovative Materials and Solutions for Harsh & Corrosive Process Streams

At CG Thermal we are decidedly customer-focused, and approach each new project with a desire to achieve our customer’s goals and process requirements in the most efficient and cost-effective manner. We have particular expertise in corrosive and high temperature process streams, and provide a range of services from individual equipment to full turnkey systems to engineering design and plant layout consulting.

Let’s discuss your harsh and corrosive process stream today!