Proven in service on both carbon steel and SST pickling lines, many CG Thermal customers are standardizing on the Umax design for all future pickling exchanger purchases.

Corrosion and Erosion Resistant Tubing

and Erosion Resistant Tubing

All pickling liquors pose corrosion challenges. A few heat transfer media will hold up against those containing HCL for a period of time, and even less against those containing HF and HNO3. A real and practical solution is Umax Advanced Ceramic tubes. Made of alpha sintered silicone carbide, these tubes are totally inert and will not corrode in these pickling acids or any other chemistry for that matter. They are twice as hard as tungsten, so they are also erosion resistant.

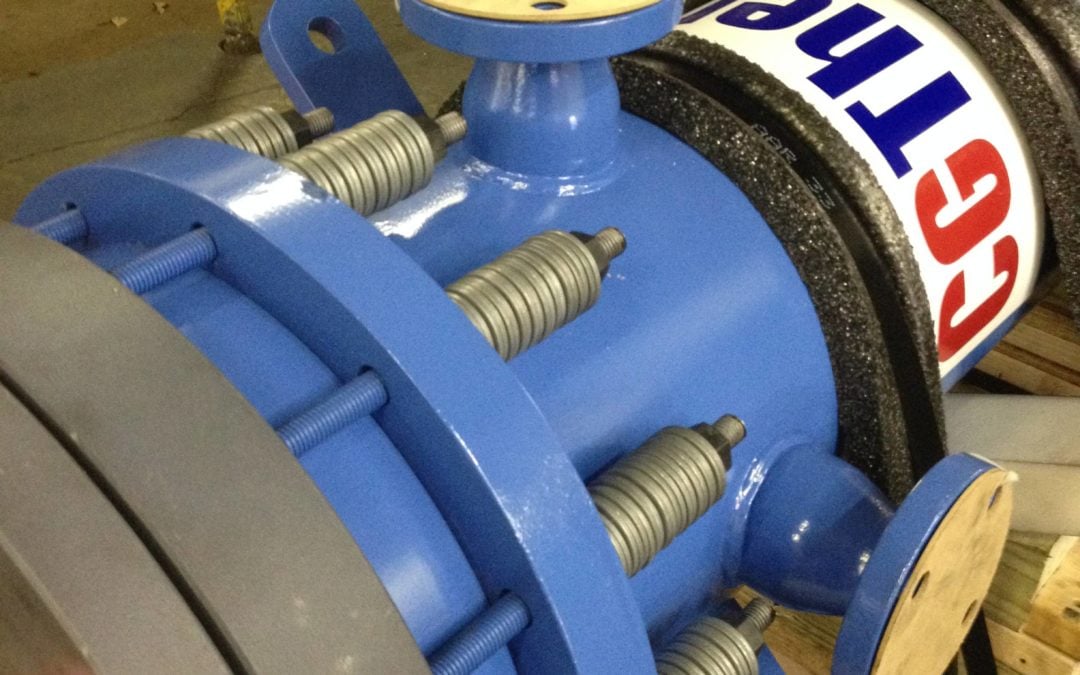

Onsite Serviceability with Individual Tube Seal Technology

To say the operating conditions of a pickling line are strenuous might be considered an understatement. These run long hours at high temperatures and pressures with frequent changes in load, process fluid and even service fluids. So, things happen. And when they do, the Umax design, with each tube individually sealed to the tube sheet, helps minimize the impact of the unexpected. If a system upset results in a broken tube, stocked spare parts can be used to complete a field repair.

Consider the cost savings; No shipping costs, minimal replacement material and labor costs, and minimal loss of production time!

Feedback from customers confirms these cost and time saving benefits. We heard recently from a maintenance manager elated by the ease of replacing a tube right there on site. After a system upset, he was able to replace a broken tube and get the unit back in service within one shift. He thanked us for the not only a design that went easy on his maintenance budget, but also the minimal downtime that kept the other plant folks happy. He continues to standardize on the Umax Ceramic for all pickling exchangers.