PAST PROJECTS

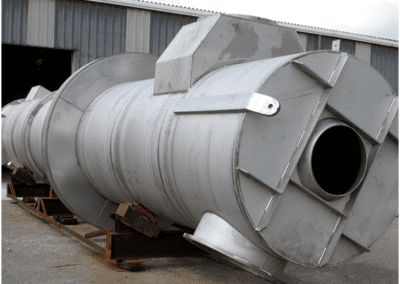

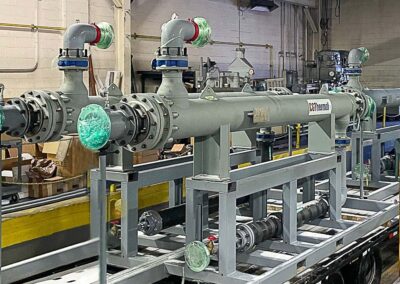

Product solutions using only the most suitable materials and technologies available worldwideWe invite you to browse a collection of our past projects to better understand the scope of expertise in harsh and corrosive process streams. At CG Thermal, we proudly deliver the product solution using only the most suitable materials and technologies available worldwide. The success of our customers is paramount and we maintain a personal stake in the successful implementation of the result.

Below is a sampling of just a few completed projects from the many markets we serve. From steel pickling to remediation to specialty chemicals, the range of our product offerings is vast, and there’s truly no project too big or small for our team. Click here to learn more about the Markets We Serve.