ACHEMA 2024

This June, the CG Thermal team will travel to Frankfurt, Germany for the most anticipated event in our industry: ACHEMA 2024! We’ve been planning this trip since the last ACHEMA show in 2022 and we’re excited to share our expertise in heat and mass transfer with new and old audiences alike.

This June, the CG Thermal team will travel to Frankfurt, Germany for the most anticipated event in our industry: ACHEMA 2024! We’ve been planning this trip since the last ACHEMA show in 2022 and we’re excited to share our expertise in heat and mass transfer with new and old audiences alike.

Alongside our broad range of time-tested heat transfer solutions, we’ll be showcasing our AirBTU VPRR High-Temperature Gas-To-Gas Recuperator, capable of design-in reliability up to 1200C! Our heat exchangers and process equipment are very well-suited for a range of industries including Green Energy applications, battery production and recycling, as well as strong acid production, dilution, storage, and much more! Click here to see all of the Markets We Serve.

If you’re so inclined, please use the link provided for a free entry ticket and come say “hallo” to the CG Thermal crew in Hall 4.0 at Booth D66. Hall 4.0 is home to the Thermal Process arm of the conference, featuring a wide range of products and services in the chemical processing industry.

We’re ready to discuss your harsh and corrosive process streams, and possibilities in Process System Design.

A note from ACHEMA:

“Modern, interactive and always up to date: With a unique range of topics, exciting innovations and new event formats, the world’s leading trade show for the process industries brings together experts, decision makers and trendsetters from all over the world.” – ACHEMA 2024

We hope to see you there!

Innovative Materials and Solutions for Harsh & Corrosive Process Streams

At CG Thermal we are decidedly customer-focused, and approach each new project with a desire to achieve our customer’s goals and process requirements in the most efficient and cost-effective manner. We have particular expertise in corrosive and high temperature process streams, and provide a range of services from individual equipment to full turnkey systems to engineering design and plant layout consulting.

Let’s discuss your harsh and corrosive process stream today!

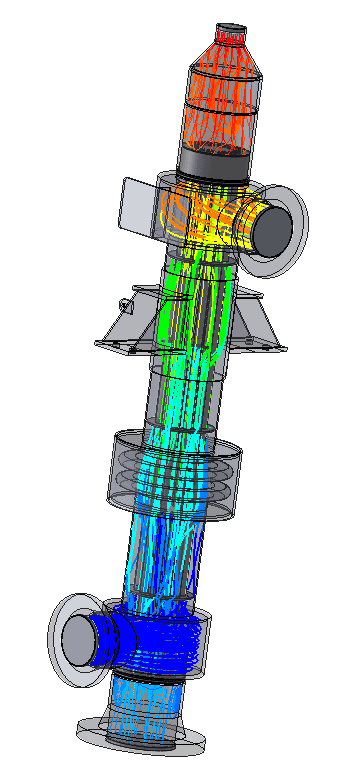

AirBTU VPRR: High Temperature Energy Capture

Are you looking to improve the reliability of your high-temperature heat transfer equipment? By integrating our AirBTU VPRR heat transfer solution, industry professionals can avoid common pitfalls and “design in” reliability and efficiency. The AirBTU VPRR is designed to:

- Avoid cold-end corrosion. The introduction of low-temperature air can result in cold spots within a recuperator, causing condensation of some constituents of the process gas stream. The resulting reaction between this corrosive condensate and the heat exchanger surface is commonly referred to as cold-end corrosion. This destructive mechanism is “designed out” of the AirBTU VPRR, making it the ideal Heat Exchanger for Sulfuric Acid Applications.

- Eliminate stress failures. Temperature gradients across the tube bundle can lead to uneven stress concentrations at the tube-to-tube-sheet connections. These result in tubesheet failures with subsequent losses in production and costly repairs. We design in uniformity to eliminate this failure mode.

- Reduce pressure drops. Our VPRR features a proprietary design that reduces pressure drops for the best energy efficiency.

- Maximize thermal efficiency. Flow dynamics modeling is used to evaluate tube layouts and pass arrangements to create a symmetric design with optimal film coefficients and overall heat transfer rate. The resulting design requires less surface area and minimizes material and fabrication costs.

- Minimize maintenance downtime. In addition to minimizing failures caused by cold end corrosion and uneven mechanical stresses, we can “design-out” the potential for fouling.

Process System Design

Turnkey Packaged System — Custom designed skid package system may include instrumentation, PLC, HMI, piping, electric and platforms, ladders, and other safety features per job requirements

- Consulting Services — Trouble-shooting, optimizing, and evaluating of existing plant operations

- Engineering Design Package — Complete engineering and operations design and documentation including Haz-Op review on customer site, and controls and control instrument loops

- Major Equipment Package — Exchangers, vessels, pumps, filters, controls, drums, tanks, etc.

Turnkey Packaged System — Custom designed skid package system may include instrumentation, PLC, HMI, piping, electric and platforms, ladders, and other safety features per job requirements

Turnkey Packaged System — Custom designed skid package system may include instrumentation, PLC, HMI, piping, electric and platforms, ladders, and other safety features per job requirements