Visit Us at CRU Nitrogen and Syngas in Tulsa, OK

“The conference agenda delivered a mix of round tables and clinics, supported by technical papers highlighting how new technology, equipment and materials can be applied to improve safety, reliability, efficiency and productivity in production facilities. Along with the exhibition of 80+ world-class solution providers and technical experts, CRU Nitrogen + Syngas USA really is your one stop-shop for networking and professional development. ” – CRU Group

Join us at this years “must-attend” event and increase your plant’s safety. Click the button below to schedule your in-person meeting with our team.

AirBTU VPRR: High Temperature Energy Capture

Are you looking to improve the reliability of your high-temperature heat transfer equipment? Are you looking for technology that will allow you to reutilize waste heat at higher temperatures? If so, you need to visit us in Tulsa. By integrating our AirBTU VPRR heat transfer solution, industry professionals can avoid common pitfalls and “design in” reliability and efficiency. The AirBTU VPRR is designed to:

- Avoid cold-end corrosion. The introduction of low-temperature air can result in cold spots within a recuperator, causing condensation of some constituents of the process gas stream. The resulting reaction between this corrosive condensate and the heat exchanger surface is commonly referred to as cold-end corrosion. This destructive mechanism is “designed out” of the AirBTU VPRR, making it the ideal Heat Exchanger for Sulfuric Acid Applications.

- Eliminate stress failures. Temperature gradients across the tube bundle can lead to uneven stress concentrations at the tube-to-tube-sheet connections. These result in tubesheet failures with subsequent losses in production and costly repairs. We design in uniformity to eliminate this failure mode.

- Reduce pressure drops. Our VPRR features a proprietary design that reduces pressure drops for the best energy efficiency.

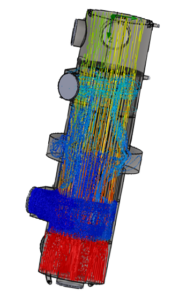

- Maximize thermal efficiency. Flow dynamics modeling is used to evaluate tube layouts and pass arrangements to create a symmetric design with optimal film coefficients and overall heat transfer rate. The resulting design requires less surface area and minimizes material and fabrication costs.

- Minimize maintenance downtime. In addition to minimizing failures caused by cold end corrosion and uneven mechanical stresses, we can “design-out” the potential for fouling.