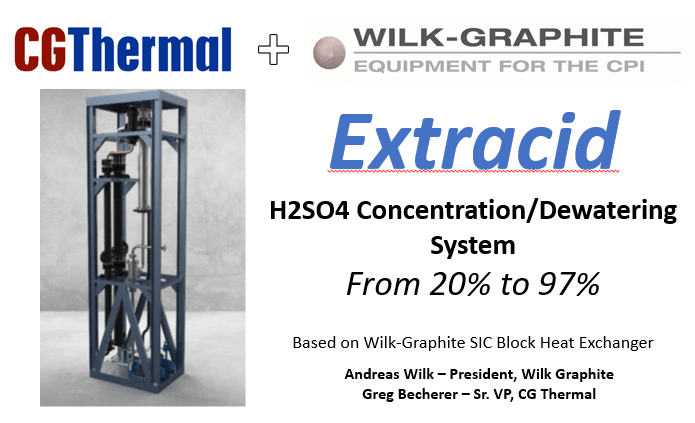

CG Thermal LLC introduces EXTRACID in partnership with Wilk-Graphite

EXTRACID is a newly developed and patented dewatering system (SCU) capable of dewatering streams of low-concentration sulfuric acid to produce up to 97% sulfuric acid under positive pressure. The unique Umax SIC Block heat exchanger design as well as other SIC components, provide for safe reliable operation at elevated temperatures. Consequently, the vaporized water from the acid can be used as process steam, resulting in up to 70% regained energy back into the system. Additionally, the system’s small footprint saves on investment and operational costs.

An advancement in design & engineering

This next generation system builds on the success of the Umax® Block Advanced Ceramic Heat Exchanger. Its infrequent need for maintenance, universal resistance to corrosion, and resistance to fouling makes it particularly well suited to operate in the harsh conditions required by this system.

The EXTRACID system’s ability to maintain a constant outlet concentration, even when the inlet varies, provides the flexibility required at most facilities. As a CG Thermal technology, it boasts both OPEX and CAPEX advantages. A small footprint and modular design make it a practical addition to your facility providing impactful operational savings in an economical design.

The breakthrough technology of the Extracid system is made available through the partnership of Wilk-Graphite and CG Thermal. Allowing the dewatering of weak H2SO4 streams under pressure, the system generates high quality steam, instead of consuming it as is the case in traditional multi staged systems operating under a vacuum.

Key features:

- Produces process steam as useable product

- Up to 70% energy recovery

- Low investment and operation cost

- Constant product concentration even at variable inlet

- Skip mounted

- Small footprint

- Decomposes Organics

- Resistant at HF and other component

- Excellent for High purity application

High reliability:

- Excellent corrosion resistance

- Low maintenance

- Thermal shock resistance

- Fouling resistance

Conclusion

Finally, it’s time to step into the 21st century. In addition to producing high concentration sulfuric acid, this state of the art system provides clean steam that can be reused for expansion or to replace a steam generator. In addition to saving valuable production space due to its small footprint, you will realize both CAPEX and OPEX savings. Contact us today to make the upgrade!