Is it more cost-effective to replace or refurbish a graphite heat exchanger? Regular maintenance and inspection by a CG Thermal field technician will ensure your process stream experiences as little downtime as possible. During a service visit, the heat exchanger is inspected in its entirety, including tubes, domes, and all related components. Typically refurbishment can be employed, minimizing both downtime and operating costs.

Heat Exchanger Refurb: A Case Study

Heat Exchanger Refurb: A Case Study

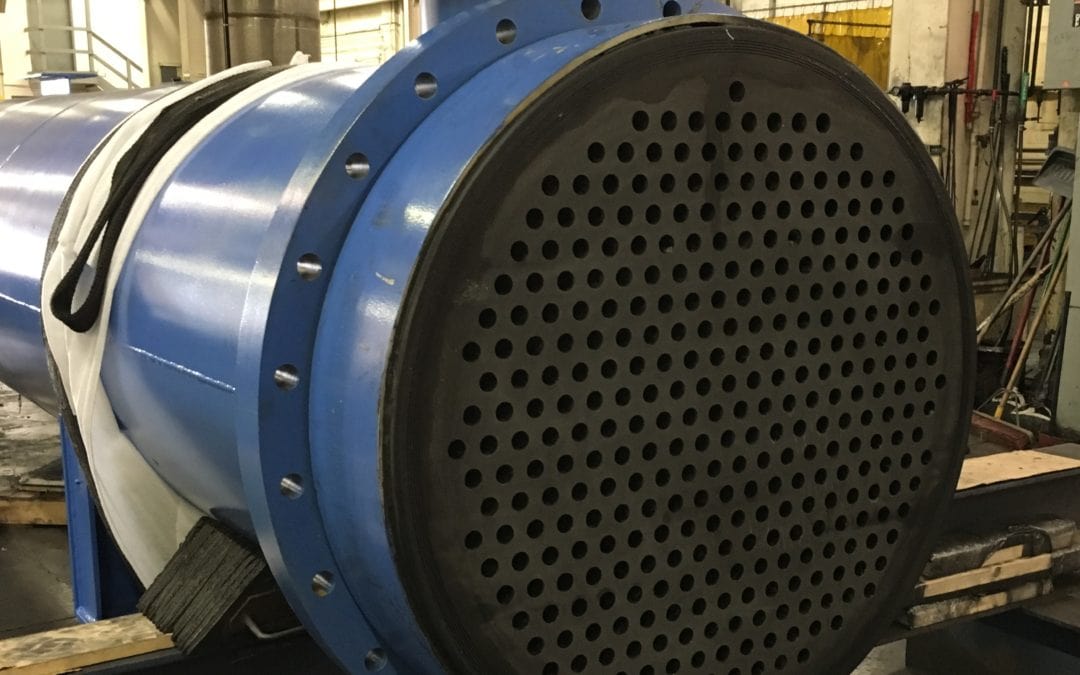

This 34″ diameter shell and tube heat exchanger with a 240″ long graphite tube bundle is a vital component of our customer’s operations. Their process fluid composition is very aggressive and compatible with very few heat transfer media. Our customer investigated other options, but found that our Impervite® graphite shell and tube was the most cost effective solution.

The impregnated graphite does have its limitations however. Over time, the process will corrode the graphite. Alpha sintered ceramic tube would be an ideal heat transfer media for this process since it is universally corrosion resistant to most all chemicals up to 400F. If the thermal load was less, ceramic would be an obvious choice. However, due to the heat transfer area required for this process load, Impervite® graphite was found to have the lowest life cycle cost and was chosen as the heat transfer media.

Field assistance and service

When it’s time to refurbish a graphite heat exchanger, CG Thermal is here to help. Recognizing the aggressiveness of process fluid, regular unit inspections were scheduled. After 18 months in service, a loose tube is found during shutdown inspection. The process is critical and downtime is costly. A CG Thermal Field Service Technician assisted by onsite service technicians field tested the unit, identified and plugged the failed tubes, and arranged a service appointment at the CG Thermal facility. Once instructed by our Field Service Technician, spare materials were kept in stock, and onsite personnel plugged tubes when necessary.

Inspection and Recommendations

During a scheduled maintenance shutdown, we made arrangements for the unit to ship to our facility in Twinsburg, OH for inspection. Normally, conducting a process side test would be routine in this situation. However, due to a significant number of plugged tubes and obvious tube sheet erosion, there was no need. Clearly, the service life of the tube bundle had been exhausted, and replacing the entire tube bundle was necessary to restore this heat exchanger.

Our in-house technicians inspected and tested the domes and all other components. The shell and all the steel components that only saw the service fluid or atmosphere, were all in good operational condition. We submitted our work order summary and recommendations to the customer.

Conclusion: Refurbished to OEM standards

The customer agreed with the recommendations explained in the work order summary. The graphite components were replaced and all steel components were sandblasted and painted, and new hardware was installed. Our customer had a refurbished unit to OEM standards for a fraction of the cost to replace with new.

Heat Exchanger Refurb: A Case Study

Heat Exchanger Refurb: A Case Study