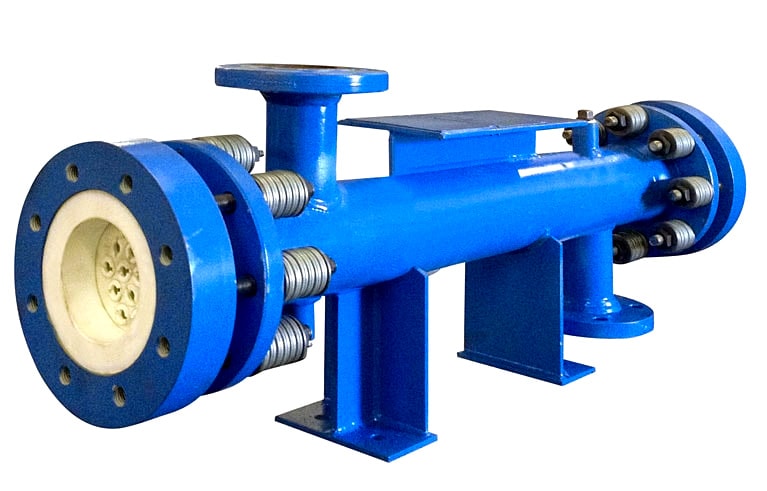

UMAX SiC Ceramic Heat Exchangers

For harsh and corrosive process streamsMeet the most universally corrosion-and-erosion resistant material in the chemical processing industry.

Heat exchangers are a critical component in your chemical and metal processing systems. When not correctly engineered, heat exchangers fail mechanically and thermally, resulting in the essential loss of production time.

And when your processes involve highly corrosive acids or abrasive fluid streams, you must give considerable attention to your heat exchanger’s materials of construction and configuration.

CG Thermal designs and constructs its Umax Advanced Ceramic shell and tube heat exchangers to tolerate hostile operating environments. With alpha-sintered silicon carbide (SiC) tubes, our UMAX heat exchangers withstand the harshest process applications with extremely high corrosion and erosion resistance and superior thermal conductivity.

The Umax Advanced Ceramic heat exchanger is a higher-value and longer-lasting alternative to reactive metal, nickel alloy, and graphite heat exchangers, with unmatched levels of corrosion resistance, abrasion resistance, and thermal efficiency for harsh process conditions.

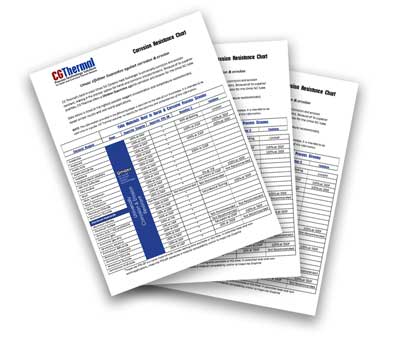

Download Our Heat Exchanger Corrosion Resistance Charts

This essential reference guide maps the corrosion resistance of tube materials at the highest possible reagent concentration and temperature recommended. Now you can compare Umax SiC Advanced Ceramic alongside Impervite Graphite, Impervirte PPS-GR, Hastelloy C, and Tantalum.

Compare various heat exchanger tube materials against nearly 300 chemical reagents!

Corrosion & Erosion Resistant Heat Exchangers

Whether you are working with mixed acids, free halogens, hydrofluoric acid, or caustics, the Umax Advanced Ceramic Heat Exchanger is designed to provide optimal results in your heat transfer application.

This ceramic heat exchanger combines a shell-and-tube design with alpha sintered silicon carbide ceramic tubes using a highly engineered individual tube sealing system coupled with PTFE tube sheets.

This ceramic heat exchanger combines a shell-and-tube design with alpha sintered silicon carbide ceramic tubes using a highly engineered individual tube sealing system coupled with PTFE tube sheets.

The result?

A durable and innovative product that can perform across a broad range of harsh environments. These units are inherently universally resistant to corrosion, erosion, and thermal shock due to their exceptional strength properties, extreme hardness, and lack of free silicon.

High resistance to fouling

Furthermore, the materials used to construct them are highly resistant to fouling. Should a tube require replacement, it can be quickly and easily accomplished without disturbing any other tubes. This process not only minimizes downtime but is also highly economical as no specialized welding procedures or special tools are needed for Umax tube replacement.

Key Benefits of the Umax Advanced Ceramic Heat Exchanger

No corrosion

Advanced ceramics such as SiC are very chemically stable, making them suitable for operating environments involving aggressive chemical compounds (strong acids, bases, oxidizers, etc.).

No erosion

Because of its extreme hardness, SiC ceramic tube is extremely resistant to erosion.

Low fouling

The tight structure of SiC ceramic makes for a smooth surface, which is inherently resistant to fouling. This increases the operational time between maintenance downtimes as compared with other heat transfer materials and thereby your overall productivity.

Ease of maintenance and repair

Most Umax heat exchanger repairs are easy and quick to complete using common shop tools. Repairs can typically be done onsite with minimal downtime. SiC tubes can be pressure washed, mechanically or chemically cleaned without causing damage.

Immune to thermal shock

The high thermal conductivity and low CTE, coupled with strength of SiC ceramic tubes makes them essentially immune to thermal shock. This makes them capable of withstanding the extreme and rapid temperature changes often associated with heat transfer applications.

Industries and Applications

Umax Advanced Ceramic Heat Exchangers are capable of handling severely corrosive and abrasive liquids and gases without the erosion, corrosion, and oxidation issues associated with heat exchangers made from alternative materials. This makes them well suited for:

- Chemical milling. Ceramic heat exchangers are often used in chemical milling operations involving hydrofluoric and nitric acid.

- Titanium/SST and nickel alloy pickling. Heat exchangers with ceramic components offer the corrosion resistance required to tolerate a variety of hydrofluoric and nitric acid pickling treatments for metals.

- Sulfuric acid dilution. Umax ceramic can withstand all concentrations of H2SO4 making it a preferred choice for battery producers or specialty chemical toll manufacturers.

Other common uses for ceramic heat exchangers include:

- Carbon steel processing with hydrochloric acid

- Applications involving high-purity electronic chemicals

- Halogens (Br, fluorine, chlorine)

- Mineral processing (hydrofluoric acid, sulfuric acid, Caro’s acid, and mixed acids)

- Specialty chemical processing

Contact CG Thermal

Contact CG Thermal today to learn more about our Umax Advanced Ceramic heat exchanger line, as well as customer specific heat exchangers, fluid handling equipment, or in-house thermal and mechanical design capabilities.

Call us today or use our contact form.