Join CG Thermal at Heat Exchanger World Americas 2025, taking place October 15–16, 2025 at the NRG Center in Houston, Texas. This annual event brings together manufacturers, fabricators, EPCs, service providers, and end users to address today’s biggest challenges in heat transfer — from rising energy costs to sustainability demands

Visit us at Booth 1409 to explore our proven solutions for harsh and corrosive process streams, including:

Impervite® Advanced Graphite – resilient and efficient in aggressive chemical environments.

Umax® Advanced Ceramic – universally corrosion- and erosion-resistant, delivering unmatched service life.

Custom Process Systems – from sulfuric acid dilution and regeneration to high-temperature gas-to-gas recovery, our engineered systems help plants minimize downtime and maximize performance.

With thousands of attendees and a dynamic mix of technical sessions and exhibits, Heat Exchanger World Americas offers a unique opportunity to connect with experts driving innovation in the industry. Our engineering and sales team will be on hand to discuss your process challenges and help identify the right solution for your plant.

We look forward to seeing you in Houston!

“Why Attend Heat Exchanger World Americas?

The heat exchanger industry is facing a number of challenges from rising energy costs to concerns over the environment.

That’s why we’re hosting Heat Exchanger World Americas Conference & Expo in Houston TX every year. We’ve already hosted three successful conferences with thousands of attendees, and you can expect more great things from us as we continue to grow!

- The event will have something to offer for everyone – manufacturers, fabricators, service providers, fabricators, EPCs and end users.

- Attendees can network with the leading minds driving ahead innovation and excellence in the fields of heat exchanger and heat transfer equipment use, maintenance and repair.

- This event will be a two-day conference with an exhibition and technical conference

Don’t miss your chance to attend this dynamic and interactive event on October 15th-16th, 2025 at the NRG Convention Center in Houston!”

Innovative Materials and Solutions for Harsh & Corrosive Process Streams

At CG Thermal we are decidedly customer-focused, and approach each new project with a desire to achieve our customer’s goals and process requirements in the most efficient and cost-effective manner. We have particular expertise in corrosive and high temperature process streams, and provide a range of services from individual equipment to full turnkey systems to engineering design and plant layout consulting.

Let’s discuss your harsh and corrosive process stream today!

Impervite® Advanced Graphite: An Advance in Non-Metallic Materials

The Impervite® Advanced Graphite Heat Exchanger design incorporates proven tube to tubesheet seal and the field-repairability of our Umax SiC Ceramic Heat Exchanger with the quality that the industry has long associated with Impervite®. Additionally, the Impervite® Advanced Graphite tubes can be used in conjunction with our United States Patented XD tubesheet, capable of pressures up to 150 psig at 400F.

Recently, the Impervite® Advanced Graphite design received the prestigious 2023 VAALER Award for Innovation in the Chemical Industry. Click here to learn more about Impervite® Advanced Graphite and the award.

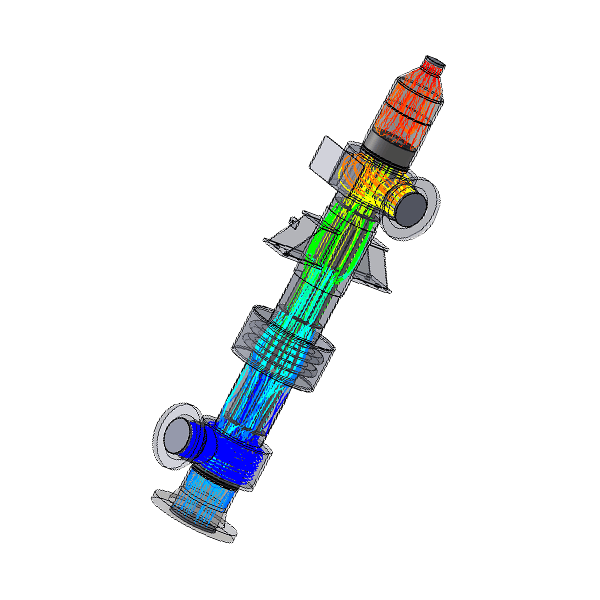

AirBTU VPRR: High Temperature Energy Capture

Are you looking to improve the reliability of your high-temperature heat transfer equipment? Are you looking for technology that will allow you to reutilize waste heat at higher temperatures? If so, you need to visit us in Pasadena. By integrating our AirBTU VPRR heat transfer solution, industry professionals can avoid common pitfalls and “design in” reliability and efficiency. The AirBTU VPRR is designed to:

Are you looking to improve the reliability of your high-temperature heat transfer equipment? Are you looking for technology that will allow you to reutilize waste heat at higher temperatures? If so, you need to visit us in Pasadena. By integrating our AirBTU VPRR heat transfer solution, industry professionals can avoid common pitfalls and “design in” reliability and efficiency. The AirBTU VPRR is designed to:

- Avoid cold-end corrosion. The introduction of low-temperature air can result in cold spots within a recuperator, causing condensation of some constituents of the process gas stream. The resulting reaction between this corrosive condensate and the heat exchanger surface is commonly referred to as cold-end corrosion. This destructive mechanism is “designed out” of the AirBTU VPRR, making it the ideal Heat Exchanger for Sulfuric Acid Applications.

- Eliminate stress failures. Temperature gradients across the tube bundle can lead to uneven stress concentrations at the tube-to-tube-sheet connections. These result in tubesheet failures with subsequent losses in production and costly repairs. We design in uniformity to eliminate this failure mode.

- Reduce pressure drops. Our VPRR features a proprietary design that reduces pressure drops for the best energy efficiency.

- Maximize thermal efficiency. Flow dynamics modeling is used to evaluate tube layouts and pass arrangements to create a symmetric design with optimal film coefficients and overall heat transfer rate. The resulting design requires less surface area and minimizes material and fabrication costs.

- Minimize maintenance downtime. In addition to minimizing failures caused by cold end corrosion and uneven mechanical stresses, we can “design-out” the potential for fouling.