Graphite Heat Exchangers

Less downtime. Lower Maintenance.

Time-Tested Heat Transfer Expertise

At CG Thermal we produce Impervite® graphite, an impervious composite consisting of a graphite base material impregnated with a proprietary resin. The composition of the base graphite must meet a very stringent specification and undergo a precisely controlled impregnation process. The result is graphite that has excellent heat transfer characteristics and can withstand the stresses resulting from temperature and pressure fluctuations and mechanical stresses common in process applications. The thermal and physical properties of CG Thermal’s Impervite® graphite make it an excellent heat transfer media.

Advantages include:

- Exceptional thermal conductivity

- Easily machined

- Capable of withstanding system stresses

- Superior corrosion resistance

- Low coefficient of thermal expansion (CTE)

- High operational safety

- Long service life

Types of Graphite Heat Exchangers for Harsh and Corrosive Environments

Due to its high thermal conductivity, chemical inertness, and resistance to thermal shock, graphite is a highly effective heat transfer medium. Consequently, our Impervite® graphite heat exchangers are engineered in a variety of designs and configurations to accommodate a wide range of process conditions and corrosive environments.. We offer the following types:

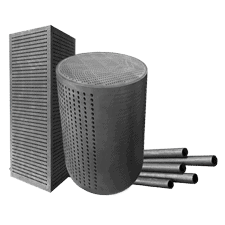

Shell and Tube Graphite Heat Exchangers

Our Impervite shell and tube heat exchangers are engineered for superior reliability and service life. Compared to other graphite heat exchangers, they offer exceptional performance and a low initial cost, resulting in an excellent lifetime return on investment. Their large cross-sectional flow area makes them ideal for low-pressure and high-fouling applications.

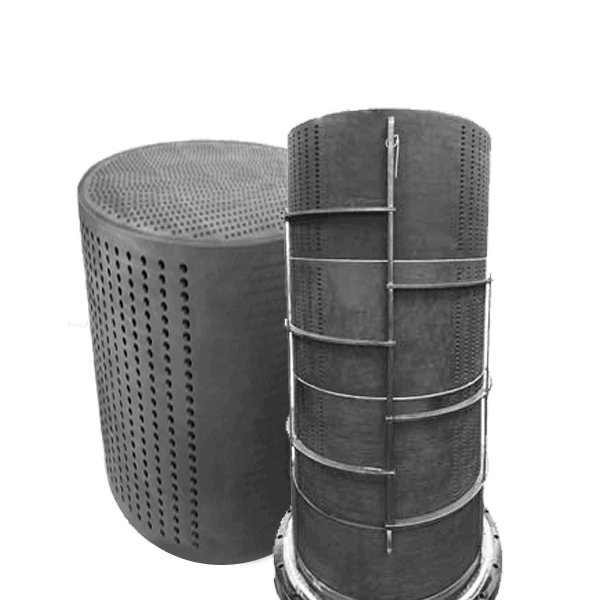

Multi-Blox Graphite Heat Exchangers

Our Multi-Blox™ cylindrical block heat exchanger features some of the longest graphite-composite blocks in the industry. This design helps reduce the need for gaskets, eliminates potential leak paths, and minimizes point loading issues. They are designed and built for non-stop service with operating pressures up to 150 PSIG.

Cubic Block Graphite Heat Exchangers

Our cubic block heat exchangers offer the greatest efficiency with the highest heat transfer capabilities in the smallest space. They are exceptionally durable and provide easy access to service holes for cleaning and maintenance. Their design makes them ideal for interchange service and high-fouling applications.

Why Use Impervite® Graphite in Heat Exchangers?

A Brief History of Graphite

The composition of the graphite can be adjusted to achieve different mechanical, thermal, and electrical characteristics for different applications. Graphene is a highly crystalline graphite used for its excellent electric conductivity. Large-grain graphite is commonly used for electrodes in steel production. Graphite is a result of the solid-phase transformation of the amorphous state of carbon to its softer, crystalline state. Graphite is the most stable form of carbon. Natural graphite is formed by subjecting carbon to 750°C at 75,000 psi for about 10 million years.

In the late 1800s, Edward Acheson, founder of the Carborundum Company, accidentally manufactured synthetic graphite while trying to create synthetic diamonds. Instead, he found that at ambient pressure amorphous carbon can be converted to crystalline graphite at 2300-3000°C.

Graphite exhibits the properties of a metal and a nonmetal. The metallic properties include high thermal and electrical conductivity. The nonmetallic properties include inertness. This resistance to corrosion allows graphite to withstand a wide range of harsh and corrosive process streams. Graphite is particularly well suited for use with strong reducing acids with high chloride contents (e.g., hydrochloric acid). In addition to hydrochloric acid, other common applications include evaporation, condensation, or simple heating and cooling of nitric acid, phosphoric acid, and sulfuric acid.

At CG Thermal, we are dedicated to providing our customers with innovative solutions for heat and mass transfer, storage, and fluid transport. Equipped with more than 150 years of combined experience, we not only design and manufacture superior graphite heat exchangers, but we also design the systems that require those graphite heat exchangers.

Increase Your Plant Productivity With CG Thermal

Graphite heat exchangers are an excellent option for heat transfer applications involving highly corrosive fluids. If you need graphite heat exchangers for your facility, turn to the experts at CG Thermal.

At CG Thermal, we are committed to ensuring your operations run smoothly and reliably with minimal downtime. Our experts have the industry knowledge necessary to design and manufacture heat exchangers that can withstand your harshest process requirements.

To learn more about our graphite heat exchanger solutions or discuss your requirements with one of our experts, contact us today.