Impervite® Advanced Graphite Heat Exchanger

Innovative Technology Improving Reliability and Serviceability

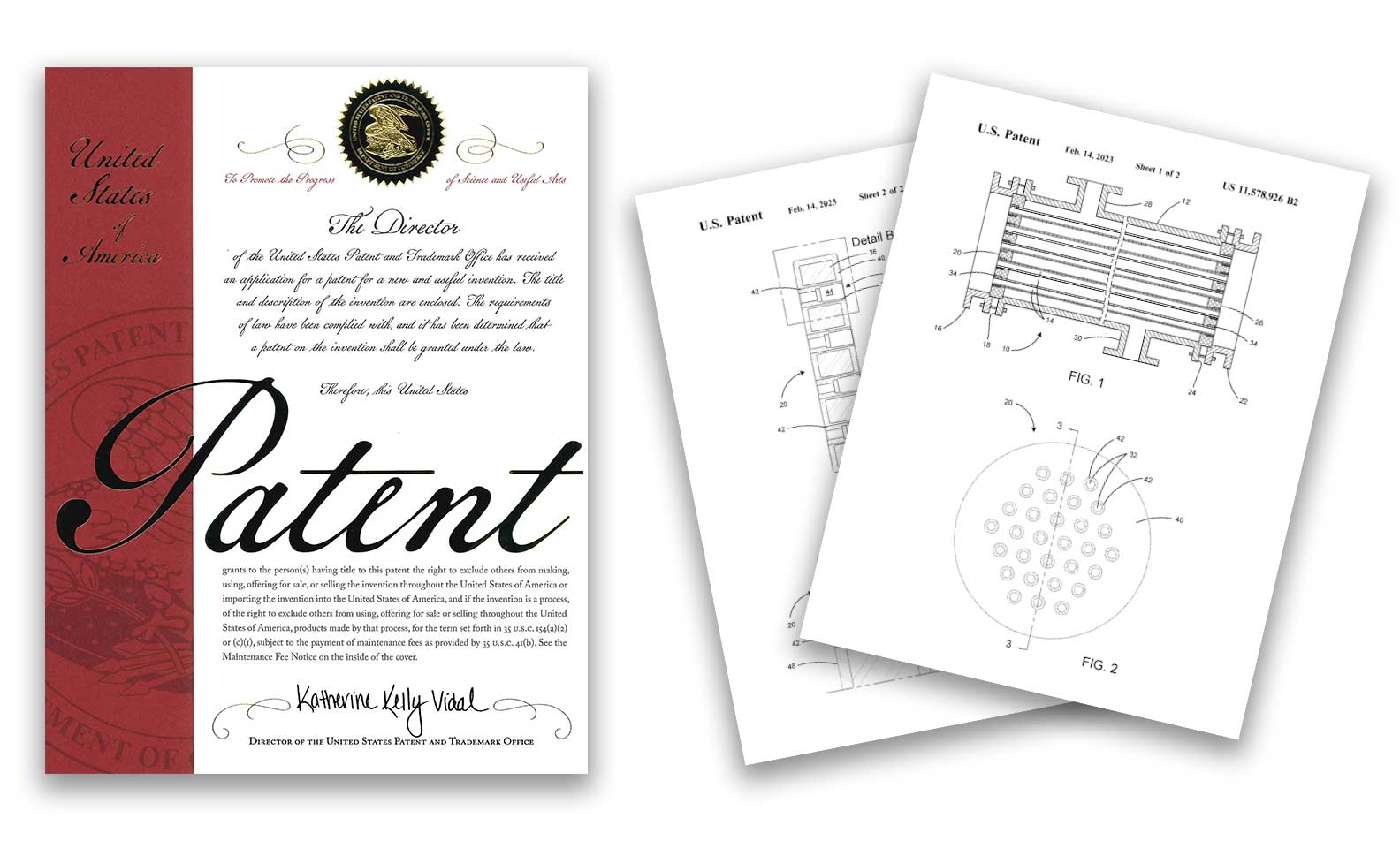

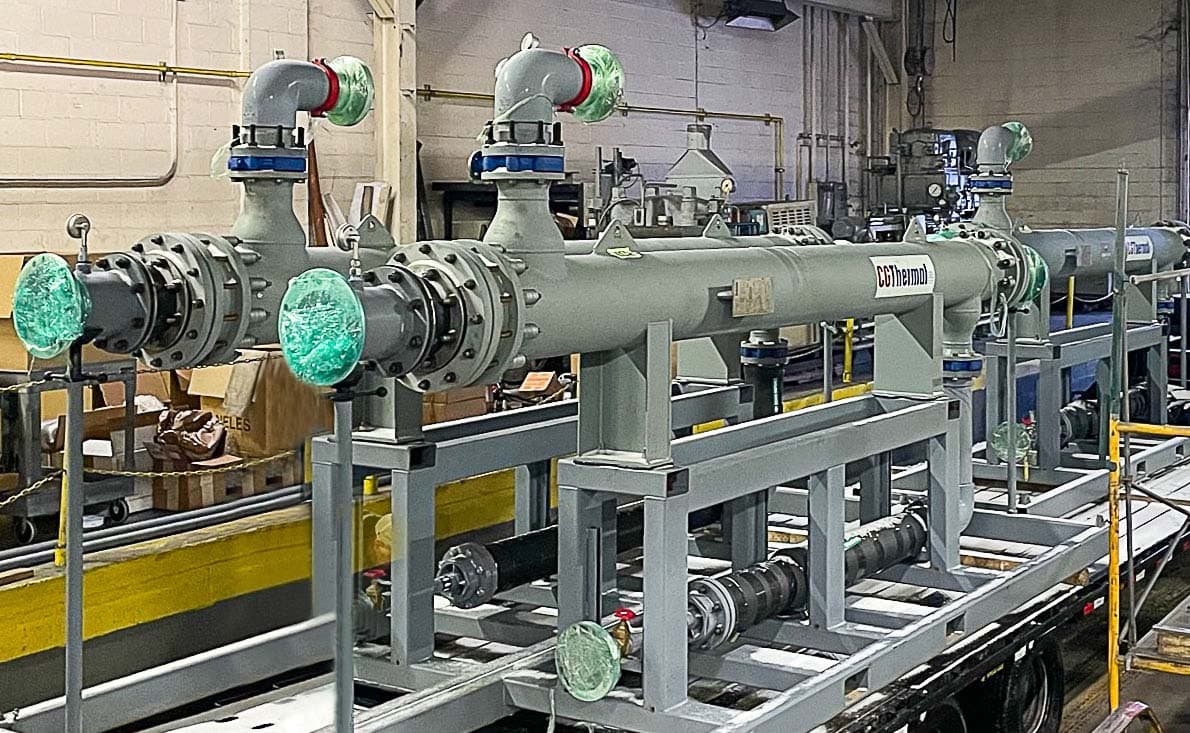

The Impervite® Advanced Graphite Heat Exchanger design incorporates proven tube to tubesheet seal and the field-repairability of our Umax SiC Ceramic Heat Exchanger with the quality that the industry has long associated with Impervite®. Additionally, the Impervite® Advanced Graphite tubes can be used in conjunction with our United States Patented XD tubesheet, capable of pressures up to 150 psig at 400F.

Heat exchangers are a critical component in chemical and metal processing systems. If not properly engineered, the heat exchanger could fail, mechanically or thermally, causing the loss of critical production. The ability to efficiently transfer heat is fundamental when choosing a heat transfer material. Additionally, when processes involve highly corrosive acids or abrasive fluid streams, considerable attention must also be given to the materials of construction and heat exchanger configuration if productivity levels are to be maximized.

The proprietary tube in the Impervite® Advanced Graphite combines the benefits of graphite and polymer materials to provide efficiency and reliability for water treatment, heat recovery, and process chemistries. This tube material provides an envious combination of resilience to operating stresses, corrosion resistance, thermal efficiency, low fouling, and maintainability.

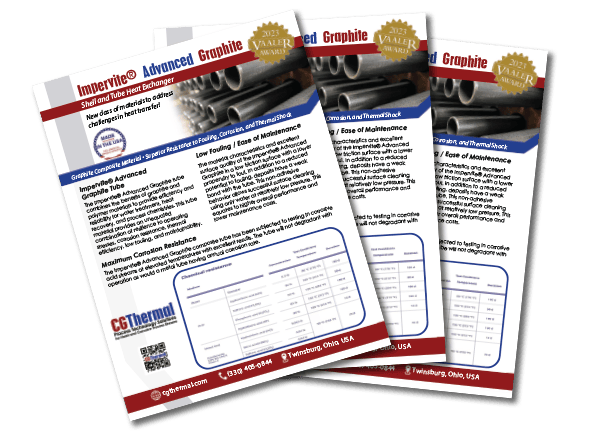

Low Fouling and Ease of Maintenance

The tubes have excellent surface quality which results in a low propensity to foul. In addition to a reduced potential to fouling, deposits have a weak bond with the tube. This non-adhesive behavior allows successful surface cleaning using only water at relatively low pressure. This equates to higher overall performance and lower maintenance costs.

Corrosion Resistance

The Impervite® Advanced Graphite composite tube has been subjected to testing in various corrosive acid streams at elevated temperatures with excellent results. The tube will not degradant with operation as would a metal tube having annual corrosion rate.

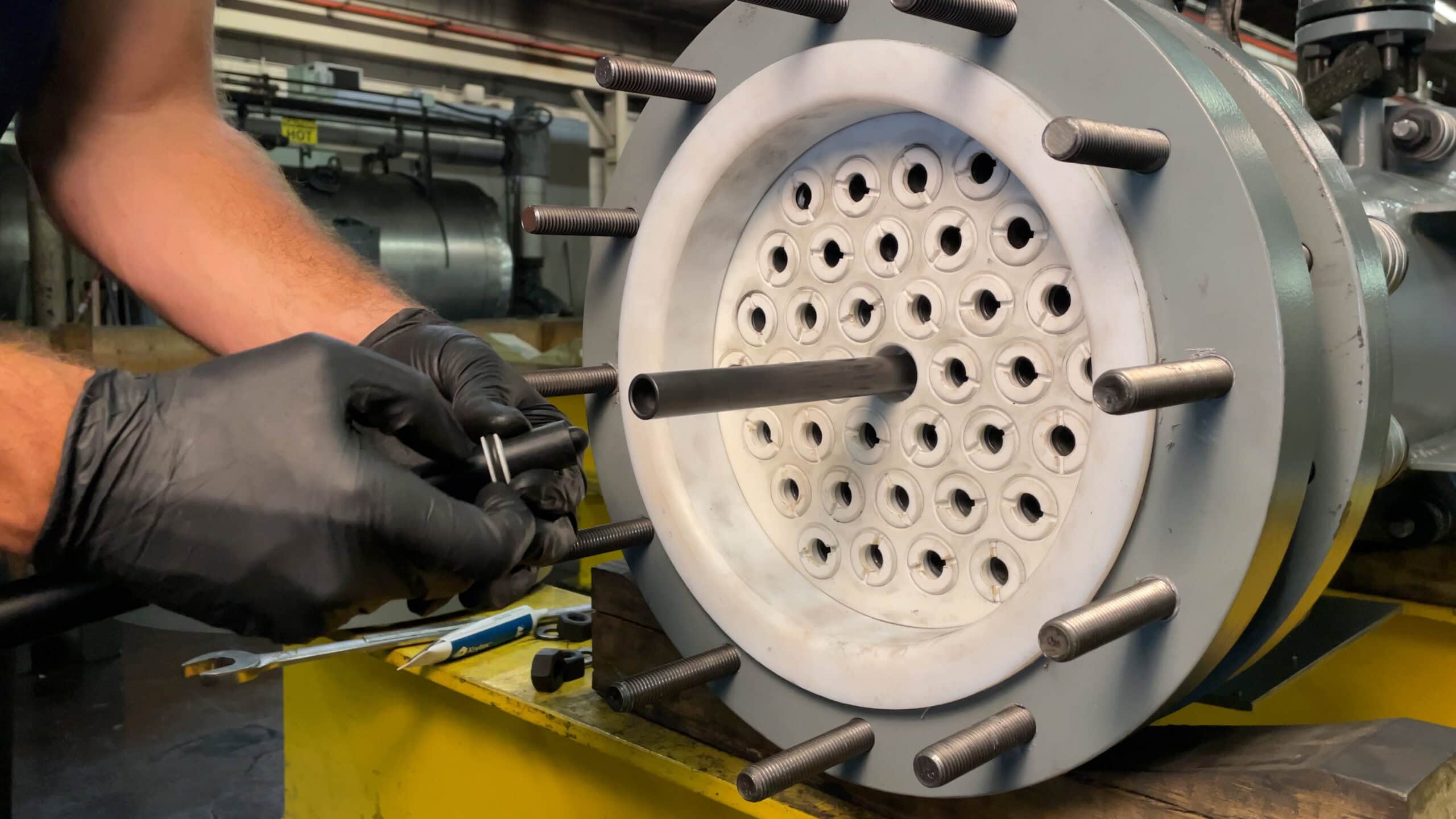

Completely Field Repairable

If ever required, individual tubes can be replaced in the field simply and economically without the need for special tools and/or highly specialized welding procedures. Gaining access to the tubes is quickly and easily accomplished. A single tube can be removed and replaced without disturbing any other tubes. This can be accomplished on site, with a simple, straightforward operation eliminating shipping concerns and minimizing downtime.

Proprietary Self-Contained Elastomeric Sealing System

The proven tube to tube sheet seal system utilizes a combination of specifically selected elastomeric seals and Teflon support rings. When coupled together with the close tolerance tube nut and tube sheet hole it results in a highly reliable, static, self-contained seal that is 100% leak free with exceptional service life.

Superior Thermal and Mechanical Shock Resistance

This composite graphite tube is much more ductile than traditional impervious graphite tubes. As a result, it is more resistant to vibration and other mechanical stresses. Additionally, its low CTE and tube to tubesheet seal of the Impervite® Advanced Graphite shell and tube exchanger build in superior resistance to thermal shock.

Extraordinary Operational Value

- High purity

- Ductile material resistant to vibration stresses

- Higher design pressure

- Corrosion resistance against most harsh process streams

- Thermal conductivity similar to that of metallic materials

- Resistant to fouling and easily cleaned

- Easily cleaned without damage to the tubes.

- Completely field repairable with common tools.

- Immune to thermal shock

Since the Impervite® Advanced Graphite is a new, innovative technology, we continue to prove compatibility with various corrosive process streams. We encourage you to conduct a test with your unique process fluid. If you would like to talk more about the Impervite® Advanced Graphite Heat Exchanger or request a tube sample, please contact us.