Korea Chem 2025: Meet Us in Seoul!

Get your passport ready and join us in Seoul, South Korea, for Korea Chem 2025! Korea Chem proves to be the premier international exhibition for chemical processing and fine and specialty chemicals. Our engineering team will showcase our time-tested Impervite® Graphite and innovative next-generation materials, including Impervite® Advanced Graphite and Umax® Advanced Ceramic. Additionally, we would love to assist your plant with unique reliability challenges in high-temperature environments.

We want to see your plant succeed!

“Your partner for success! Korea Chem is an international exhibition for the processing of pharmaceutical, bio, cosmetic, and chemical industries and for fine & specialty chemicals. Korea Chem introduces the latest trends and technologies with the exhibitors of domestic & overseas key players. This exhibition is the best opportunity to position your brand, promote new products & technology, and build new partnerships in the industry!” – Korea Chem

We look forward to discussing your harsh and corrosive process streams. Don’t miss the opportunity to connect with our team—click the button below to schedule a meeting with one of our experts, or simply stop by Booth 3G208 and say hello!

Your Partners for Success

At CG Thermal we are decidedly customer-focused, and approach each new project with a desire to achieve our customer’s goals and process requirements in the most efficient and cost-effective manner. We have particular expertise in corrosive and high temperature process streams, and provide a range of services from individual equipment to full turnkey systems to engineering design and plant layout consulting.

Let’s discuss your harsh and corrosive process stream today!

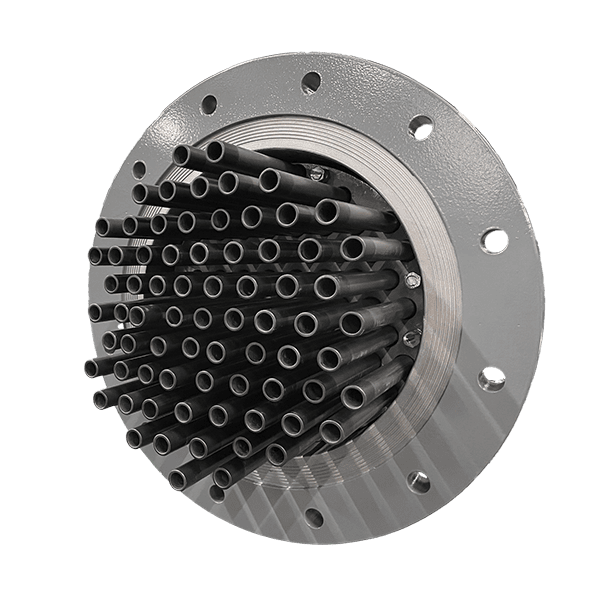

Impervite® Advanced Graphite Heat Exchanger

The Impervite® Advanced Graphite Heat Exchanger design incorporates proven tube to tubesheet seal and the field-repairability of our Umax SiC Ceramic Heat Exchanger with the quality that the industry has long associated with Impervite®. Additionally, the Impervite® Advanced Graphite tubes can be used in conjunction with our United States Patented XD tubesheet, capable of pressures up to 150 psig at 400F.

Impervite® Graphite Heat Exchanger

At CG Thermal we produce Impervite® graphite, an impervious composite consisting of a graphite base material impregnated with a proprietary resin. The composition of the base graphite must meet a very stringent specification and undergo a precisely controlled impregnation process. The result is graphite that has excellent heat transfer characteristics and can withstand the stresses resulting from temperature and pressure fluctuations and mechanical stresses common in process applications.

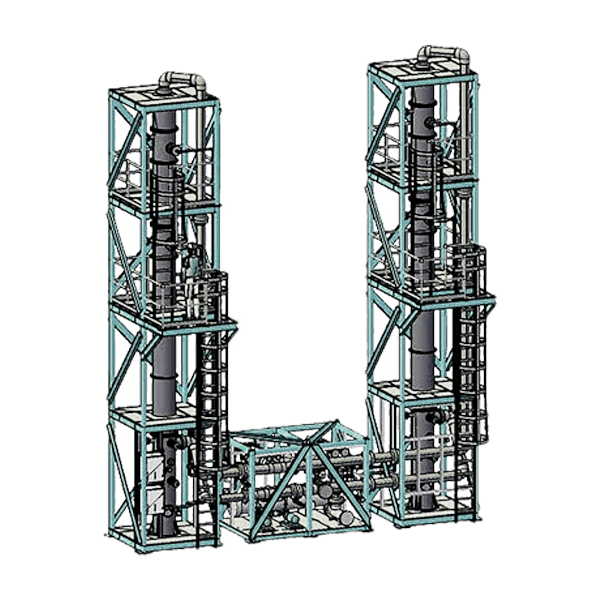

Process and System Design

We combine our extensive heat/mass transfer knowledge and fabrication capabilities with design and process expertise to deliver optimal, proven processing technology while incurring the lowest possible capital and operating expenses (CAPEX/OPEX) for the customer. Our team has a knack for understanding emerging markets and developing prototypes, as well as offering complete design and fabrication of pilot plants and modular plant systems with novel requirements.