For heat transfer applications involving sulfuric acid, the materials of construction vary based on many factors. Process fluid temperature, concentration, impurities, required service life, and cost-effectiveness all play a role in design. At CG Thermal, we use a variety of cost-effective materials including SiC ceramic, graphite, polyphenylene sulfide (PPS-GR), stainless steels, and nickel alloys.

Learn more about H2SO4 Systems

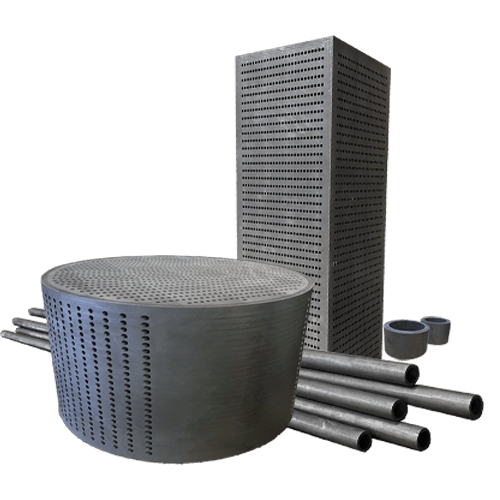

SiC Ceramic

SiC Ceramic is the premium heat transfer material because it is 100% corrosion resistant for all concentrations of sulfuric acid. Our Umax® Advanced Ceramic tube, composed of alpha-sintered silicon carbide (SiC), has no fillers or free silicon, making it universally chemically inert. All metallic material options come with a life expectancy limited by a corrosion rate whereas the Umax® advanced ceramic will not corrode.

SiC is 50% harder than tungsten carbide which allows for increased velocities of 9-15 ft/s without limiting tube life due to erosion. The increased flowrate will result in a higher heat transfer rate and reduced fouling rate, thereby reducing the surface area required. Because of SiC’s smooth, impervious surface the fouling material remains entrained in the process fluid as it passes through the tube with little resistance.

SiC is 50% harder than tungsten carbide which allows for increased velocities of 9-15 ft/s without limiting tube life due to erosion. The increased flowrate will result in a higher heat transfer rate and reduced fouling rate, thereby reducing the surface area required. Because of SiC’s smooth, impervious surface the fouling material remains entrained in the process fluid as it passes through the tube with little resistance.

Overall, these advantages result in higher thermal efficiency and less required surface area. Though the SiC material is more costly, longevity and reliability make it the material of choice for smaller systems. For large heat exchangers, the operational benefits should be weighed against the cost benefits of other materials.

Graphite

For sulfuric acid concentrations up to 75% and 345°F, Impervite® graphite is the preferred material of choice with optimal CAPEX and OPEX values. It can be considered for concentrations up to 90% under special consideration and with a more limited operating life.

With metal tubes, corrosion results in thinning of the tube wall. With graphite tubes, this is not the case. However, impervious graphite tubes in certain conditions (typically higher temperatures and higher acid concentrations), the phenolic resin used to make the tube impervious gradually degrades. This results in resin loss in the tube and lower tube strength, resulting in eventual tube breakage. In sulfuric acid concentrations above 85%, the acid can cause the graphite base to oxidize and lead to failure. Still, graphite remains an excellent heat exchanger material for many process applications requiring heating or cooling of sulfuric acid.

PPS-GR

The PPS-GR tube combines the benefits of graphite and polymer materials, providing corrosion resistance, efficiency, and reliability in sulfuric acid processes. This tube material provides an excellent combination of resilience to operating stresses, corrosion resistance, thermal efficiency, low fouling, and maintainability. This newer, promising material offers success up to 60% concentration at 290°F. CG Thermal is testing this at higher concentrations and continues to see extraordinary results. Even at its current state of verification, this material is a very cost-effective alternative to cathodically protected stainless steel heat exchangers.

Stainless-Steel Alloys

In a properly designed unit, SST construction is effective for high-temperature, gas-to-gas recuperators. Recuperators are used in applications such as catalytic operations, high-temperature energy storage, thermal oxidizers, steel mills, and steel foundries. These recuperators are capable of handling temperatures well over 1400°F. However, at the higher temperatures, it is important to understand the capabilities and limitations of the various grades of SST when determining which alloy will maintain the required strength at the design temperatures.

When it comes to liquid process streams, carbon steel and SST are common options for heat transfer materials. However, for concentrations outside 93%-99% or exceeding room temperature, only a handful of specialty alloys are acceptable. To maintain corrosion rates below the industry standard of 5 mpy, more advanced heat transfer media should be employed. For example, when concentrations exceed 70% at elevated temperatures, tantalum remains the only metallic option.

Conclusion

There are many more considerations to take when working with sulfuric acid, especially in the design, transport, and storage stages. To learn more, download this white paper.