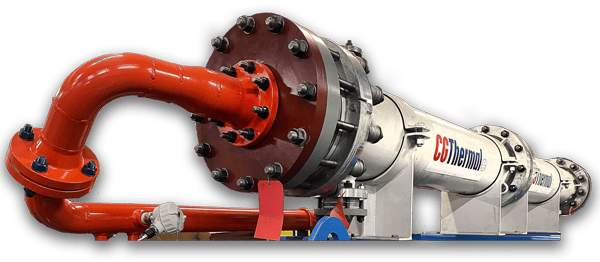

Umax SiC Advanced Ceramic Heat Exchanger

Increase Your Productivity With The Umax Advanced Ceramic Difference

The Umax SiC Advanced Ceramic Heat Exchanger, with alpha-sintered silicon carbide tubes, excels in harsh and corrosive process streams including, sulfuric acid dilution, offering industry-leading service life. Key features include:

- Exceptional strength, durability, and service life

- Superior corrosion and erosion resistance

- Low fouling surface for extended uptime

- Low maintenance costs with field-repairable design

- Excellent thermal conductivity and superior heat transfer efficiency

- Thermal shock resistance

- CG Thermal’s proprietary self-contained elastomeric sealing system with PTFE tube sheets

- Completely field-repairable with common tools

Lifetime guarantee against corrosion and erosion • Download our Umax Corrosion Resistance Chart to learn more.

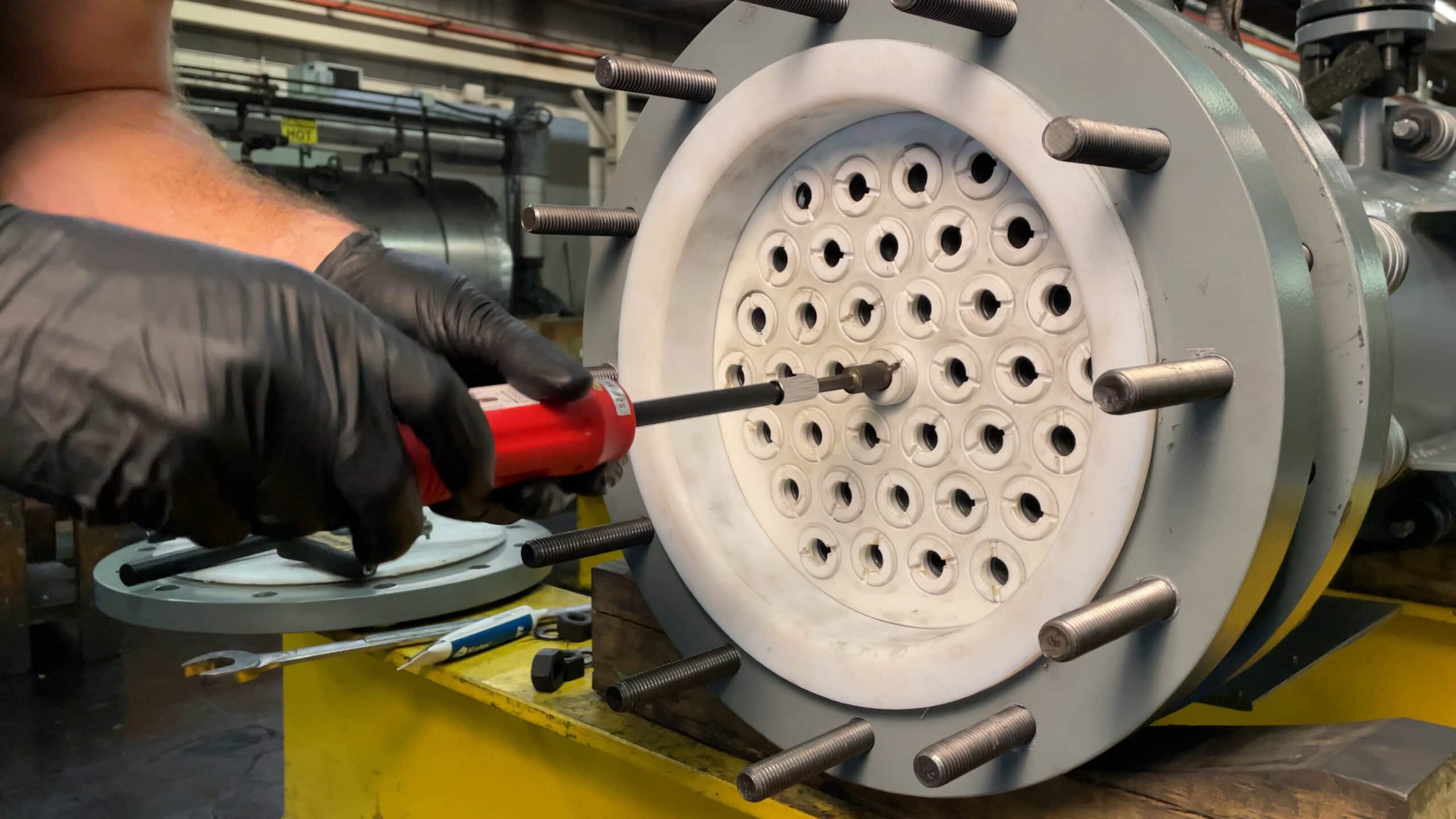

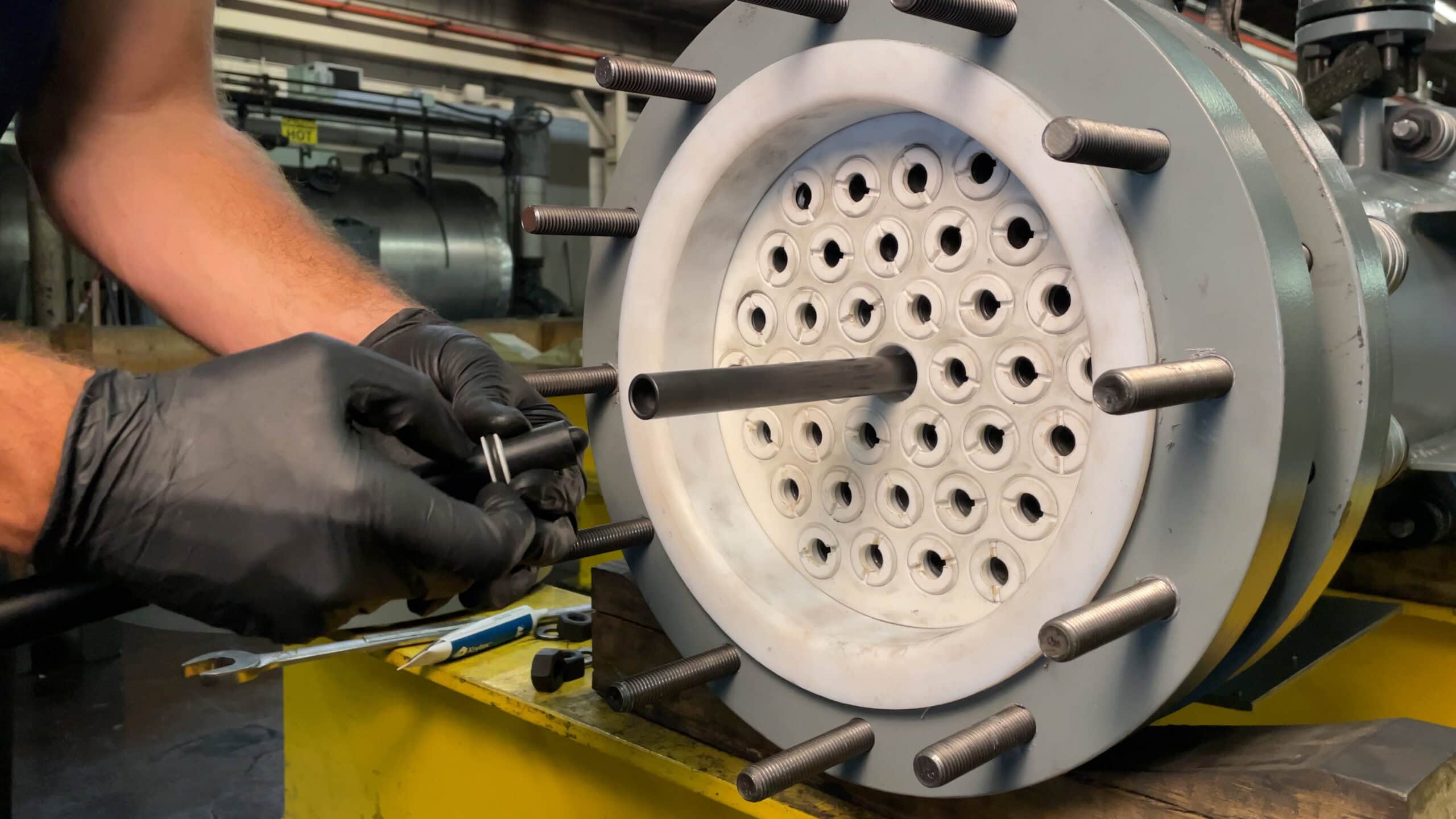

Ease of Maintenance & Repair

Designed for practicality, the Umax Advanced Ceramic heat exchanger is completely field-repairable with common tools. Individual tubes can be replaced quickly without disturbing adjacent tubes. This minimizes downtime and eliminates the need for specialized welding or equipment. SiC tubes can be pressure-washed, mechanically or chemically cleaned without damage.

Why Heat Exchanger Design Matters

Heat exchangers are critical in chemical and metal processing systems. If not properly engineered, they can fail mechanically or thermally, causing costly downtime. Efficient heat transfer and resistance to corrosion and erosion are essential for maximizing productivity. SiC ceramic has become the material of choice for extreme process environments due to its exceptional resistance and thermal performance.

Advantages of SiC Ceramic

Our alpha-sintered silicon carbide material used in Umax heat exchangers provides unmatched performance in aggressive conditions:

- No corrosion – stable in strong acids, bases, and oxidizers

- No erosion – extreme hardness prevents wear from high flow velocities

- Low fouling – smooth surfaces resist scaling and fouling

- Immune to thermal shock – capable of withstanding rapid temperature changes

- Superior thermal conductivity – higher than stainless steel, graphite, and many alloys

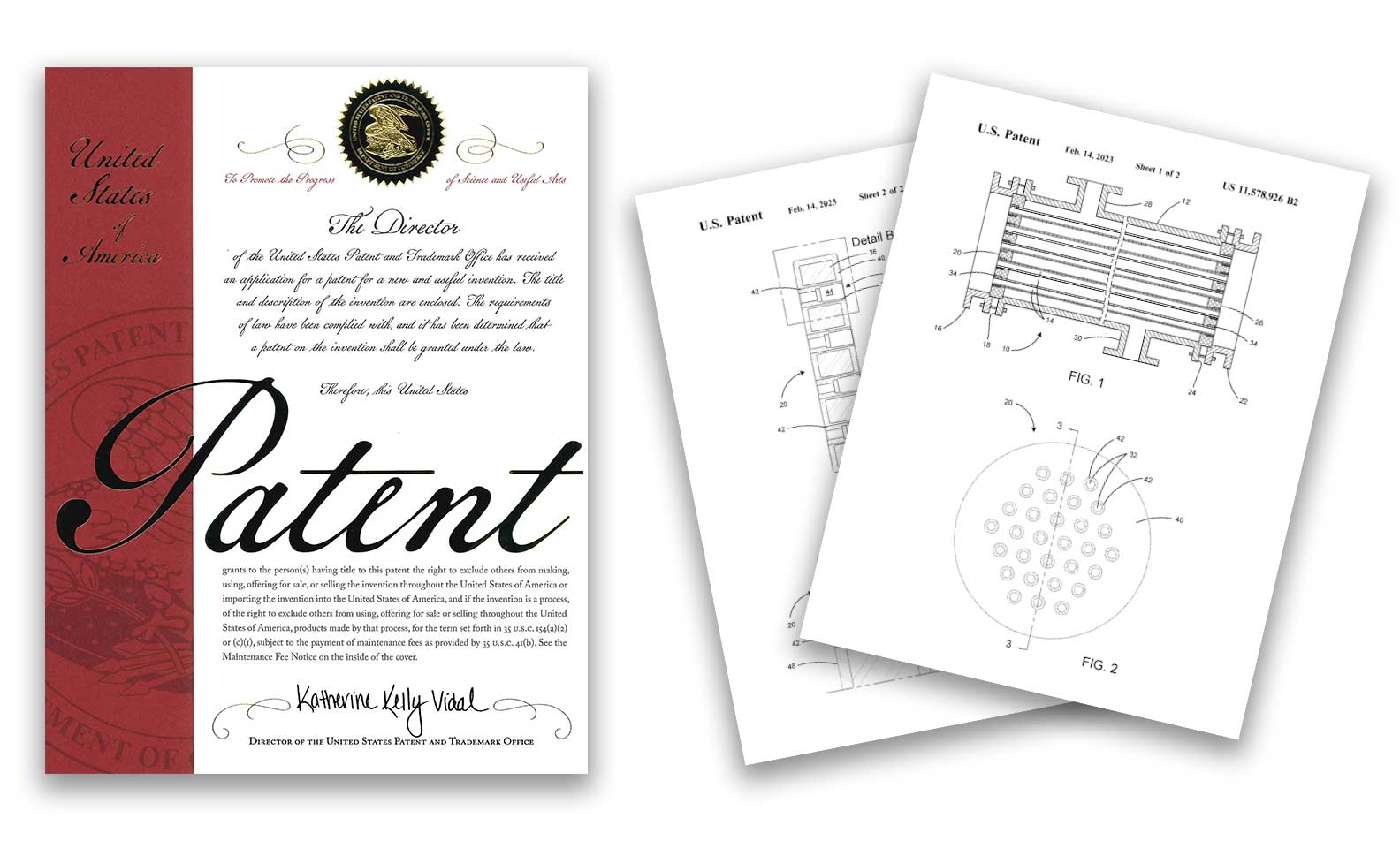

Patented Innovation

CG Thermal designs and manufactures Umax Advanced Ceramic shell and tube heat exchangers with alpha-sintered silicon carbide tubes. The Umax system is a superior alternative to reactive metals, nickel alloys, and graphite heat exchangers, offering unmatched resistance to corrosion, erosion, and thermal cycling. Our design incorporates PTFE tube sheets and our patented XD tubesheet, allowing pressures up to 150 psig at 400°F, and much larger tubesheet dimensions than traditionally available.

Industries & Applications

- Chemical milling (hydrofluoric and nitric acid)

- Titanium, stainless steel, and nickel alloy pickling

- Sulfuric acid dilution for batteries and specialty chemicals

- Carbon steel processing with hydrochloric acid

- High-purity electronic chemical production

- Halogen service (bromine, fluorine, chlorine)

- Mineral processing (HF, sulfuric acid, Caro’s acid, mixed acids)

- Specialty chemical manufacturing

Why CG Thermal

CG Thermal’s Umax Advanced Ceramic Heat Exchangers combine proven corrosion resistance, high thermal efficiency, and ease of maintenance. All units are designed and tested to ASME SEC VIII Div 1, TEMA, ANSI, and ASTM standards, in addition to our own rigorous internal requirements. Our extensive expertise allows us to customize each Umax unit to meet specific process conditions, delivering reliability and long service life.

Contact us today for a free, custom quote!